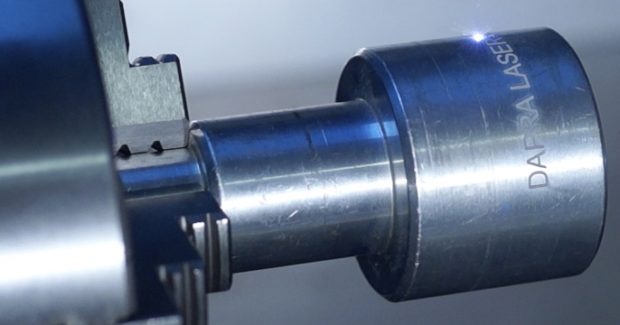

Flexible, State-of-the-Art Fiber Laser Part Marking Systems

Dapra Marking Systems helps shops determine what system configuration, laser source, lens, power source and accessories best fits their application and then tailors the system to their needs.

Posted: April 20, 2018

From turnkey Class 1 workstations with safety enclosures to open-style Class 4 configurations and fully integrated systems, Dapra Marking Systems (Bloomfield, CT) has introduced a new series of laser offerings designed for maximum performance and easy customization. They made a significant investment in product development to engineer a series of fiber laser marking systems from the ground up, pulling from a stable of state-of-the-art components to create a flexible core product line that can be quickly tailored to a shop’s individual application requirements. “Our approach is very much application driven,” said David Noonan, the director of laser marking sales and applications at Dapra. “Users shouldn’t have to force their needs into an existing box because that’s all that’s available to them. Our core systems are very easy to customize, on a very cost-effective basis. We talk to each shop and help them determine what system configuration, laser source, lens, power source and accessories will be the best fit for their application, and we create a system that is tailored to their needs.”

These laser systems feature:

- Fiber and DPSS laser sources from 3 Watts to 100 Watts.

- Class 1 enclosures and Class 4 configurations (standard and custom).

- Manual and power programmable Z-axis options with 12 in of standard travel, custom travel lengths available.

- Optional rotary D-axis for marking round parts up to 22 lb (standard).

- Industrial fume extractors.

- Powerful, intuitive software for easy logo import, serialization, date coding, Data Matrix codes, UID and UDI syntax, and much more.

Dapra Marking Systems, 66 Granby Street, Bloomfield, CT 06002, 224-355-7052, Fax: 860-242-3017, [email protected], www.dapramarking.com/direct-part-marking/laser.