CGTech and Summit Join OMIC R&D

The Oregon Manufacturing Innovation Center Research and Development now has 18 partners.

Posted: April 21, 2018

The Oregon Manufacturing Innovation Center Research and Development (OMIC R&D; Scappoose, OR) continues to grow their company membership with the addition this month of CGTech (Irvine, CA) and Summit Manufacturing Inc. (Hillsboro, OR). With a total now of 15 manufacturing industry partners and three Oregon public universities, this Scappoose-based R&D facility continues to build a world-class operation to develop advanced metals manufacturing technologies.

OMIC is an advanced collaborative environment bringing together industry, higher education and government in partnership to develop new tools, techniques and technologies to address near-term manufacturing challenges through applied research and advanced technical training. OMIC is modeled after the University of Sheffield Advanced Manufacturing Research Center (AMRC; Sheffield, England) in partnership with Boeing. The collaborative partnership includes the AFL-CIO, Business Oregon, City of Scappoose, Columbia County, Columbia County Economic Team, Greater Portland Inc, Manufacturing 21, Portland Community College, Portland State University, Oregon Employment Department, Oregon Institute of Technology, Oregon Manufacturing Extension Partnership and Oregon State University.

The OMIC R&D model focuses research on helping indigenous industries increase competitiveness while creating a real partnership with and integration into the local economy. As research activities expand with high cost, high value machinery added on to the production floor, OMIC R&D is expected to eventually increase state and regional commercial productivity in manufacturing and stimulate economic growth and development. They will coordinate their applied research projects with hands-on “earn and learn” apprenticeship programs at the OMIC Training Center, led by Portland Community College, and located in a nearby facility that PCC is building. This center, scheduled to open in fall 2020, will emphasize craftsmanship, professionalism, and placing graduates into high-wage, high-demand jobs, with students completing an associate degree or certificate leading to an advanced degree. While Training Center construction is underway, PCC will have a temporary delivery site at Scappoose High School beginning in 2018.

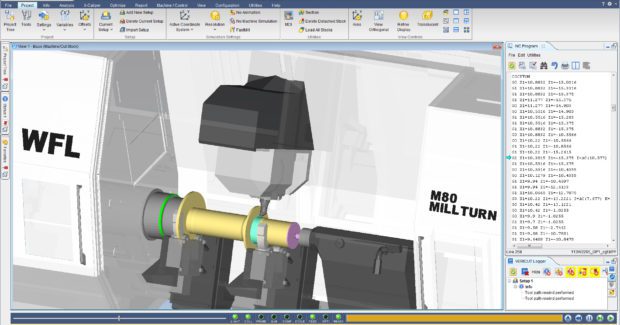

CGTech was founded in 1988 and specializes in numerical control (NC/CNC) simulation, verification, optimization, and analysis software technology for manufacturing. Since that time, their main software product, VERICUT®, has become an industry standard. With offices worldwide, this software is used by companies of all sizes, universities/trade schools, and government agencies. Summit, which was founded 25 years ago, produces high quality steel-based products for commercial and industrial use, such as modular workstations, server racks and fuel transfer tanks. Their capabilities include fabrication, laser cutting, press brake and band sawing. They also provide contract manufacturing and fabrication services.

“We welcome CGTech and Summit to our partnership and know that they will broaden our expertise in metals manufacturing,” said Matt Carter, the chair of the OMIC R&D board of governors. “Both of these organizations have high quality reputations and we know they will add great value to the innovation environment that we are creating with this impressive group of organizations. We look forward to the value that we know they both will bring to this collaborative environment.”

OMIC R&D is the fifteenth such research center established with Boeing leadership worldwide, and the first that Boeing has sponsored in the United States. Their mission is to bring together manufacturers and higher education in an innovation environment where “outside-in” applied research with faculty and university students solves real problems for advanced manufacturers while training the next generation of engineers and technologists.

“We appreciate being invited to participate,” stated Bryan Jacobs, the CGTech representative for the Pacific Northwest. “Our software is a proven tool for reducing manufacturing costs while improving quality for our existing users. Working with OMIC will help more Oregon manufacturers achieve the benefits of using our software to improve manufacturing efficiency.”

“OMIC fills a critical need in our region for economic development and innovation in advanced metals manufacturing,” added Lew Barnes, the president of Summit. “We are excited to be a part of their team and appreciate that manufacturing facilities of all sizes will benefit from the state-of-the-art technology, training and business opportunities that they bring.”

CGTech and Summit join 16 other OMIC R&D industry and university members in the Scappoose facility: ATI; Blount International; The Boeing Company; Daimler Trucks North America; Hangsterfer’s Laboratories, Inc.; Kennametal; Mitsubishi Materials Corporation; OSG USA, Inc; Silver Eagle Manufacturing; Vigor; Walter Tools; and WFL Millturn Technologies and Oregon Institute of Technology (Oregon Tech); Oregon State University (OSU); and Portland State University (PSU).

OMIC has the strong support of trade unions, including the International Association of Machinists and Aerospace Workers and the Society of Professional Engineering Employees in Aerospace, which recognize the importance of training and apprenticeship programs in growing high skill, high wage manufacturing jobs in Oregon via innovation and industry growth. Metals manufacturing is a cornerstone industry for the Greater Portland area, with current employment estimated at nearly 28,000 and approximately 600 small, medium and large metals manufacturing companies. OMIC presents a significant opportunity for the retention and expansion of these firms and the workforce in the region.