New Advances in Die Design Software

The 2018 version of SolidWorks-based Logopress3 die design software from Accurate Die Design Software can show the actual slugs underneath the punches that will be falling though the die openings.

Posted: March 15, 2018

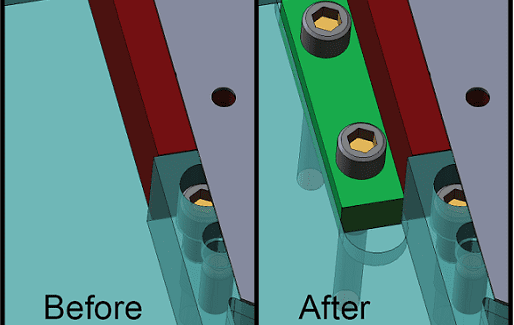

Logopress Corporation, along with their North American Technical Center Accurate Die Design Software, Inc. (Brookfield, WI), have released their new 2018 version of their SolidWorks-based Logopress3 die design software. This new version includes nearly 30 pages of enhancements and new features. While doing a strip layout and defining the cutting punches, it is very common that the slug being cut out is not the exact shape of the punch due to overlap with prior cutting punches, and also because of the strip width edge of the material. But it can be useful to understand exactly what the slug being cut looks like. Logopress3 now has the ability to show the actual slugs underneath the punches that will be falling though the die openings.

Once the strip layout is complete and the user is shown the size of the strip along with the tonnage required for the die, the designer is able to select which press the die will run in. At this point, the designer can now select from a family of tool templates that they can customize that will be fit for that particular press. This provides standardization among users and is especially helpful for new users in the company, whether they be estimators or die designers, because they can simply select the die parameters from a predefined database. Similarly, as the die designer is creating the die they are able to choose a predefined group of components from another database and insert them using the new Logopress3 Insert a Set of Components command. Not only does this insert this group of components along with all applicable fasteners and springs, it also cuts all pockets and holes automatically as well. It does all of this with a single mouse validation click. This could be a stripper form insert and its pocket and screws in one assembly, along with the form up punch in the die assembly and its related pressure pad, springs, screws and openings.

The Logopress3 die simulation and dynamic interference detection has been expanded to include not only dynamic interference, but also static interference as well. Two additional new types of motion have been added: traction and also connecting rod/crank. These new motions will especially benefit those shops that create metal stampings using four-slide and vertical slide machines, as well as those running transfer dies.

In the bill of materials (BOM), it is now possible to automatically add an oversized machining allowance to the finished dimensions of the stock size for ordering purposes.

Accurate Die Design Software, Inc., 200 South Executive Drive, Suite 101, Brookfield, WI 53005, 262-938-9316, Fax: 262-938-3933, [email protected], www.diedesignsoftware.com.