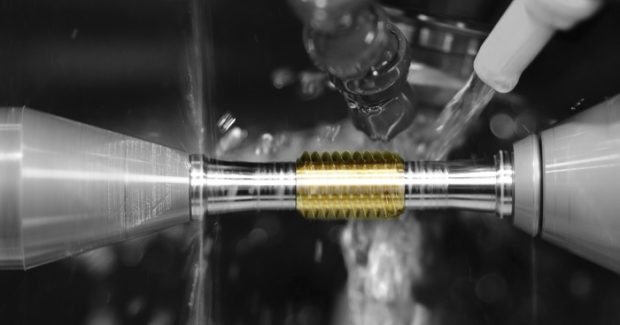

How to Finish High Precision Steel or Brass Worms Four Times Faster than Worm Hobbing

The AF110 plus 7-axis CNC gear hobbing machine from Affolter Technologies uses innovative Worm Screw Power Skiving technology to finish a high precision steel or brass worm in only six seconds – four times faster than traditional worm hobbing, which takes 25 seconds.

Posted: March 6, 2018

Innovative Worm Screw Power Skiving (WSPS) technology from Affolter Technologies SA (Malleray, Switzerland) can finish a high precision worm in only six seconds as opposed to worm hobbing, where every piece takes 25 seconds – meaning manufacturers of automotive and aircraft components can be four times faster. WSPS focuses on small worms with a module of 0.3 to 1.5 that are used in car seats or trunks, among other applications. Unlike worm hobbing, where the hob turns much faster than the workpiece, WSPS inverts the process: the workpiece turns extremely fast with two new spindles up to 12,000 rpm, while the cutter turns much slower. “Only higher quality equipment, such as our Affolter AF100 plus and AF110 plus gear hobbing machines, can reach this speed and provide the necessary stiffness at the same time,” says Vincent Affolter, the managing director of the company.

The redesigned AF110 plus 7-axis CNC gear hobbing machine uses remodeled workpiece spindles to reach these required high speeds for worms with a maximum module of 1.5 mm, cutting length up to 90 mm and part diameter up to 60 mm. “We also integrated a cutting fluid filtration system and a chip disposal system to cope with all the requirements imposed by the workpiece up to module 1.5 and the production of large volumes of chips,” explains Affolter. Ergonomics were improved through a redefinition of the machine base and surrounding, as well as the human-machine interface. The flexible AF110 plus also features a function that allows operation at reduced speeds with the hood open (Full Safety setup machine mode). The AF110 plus with WSPS can open completely new opportunities for shops that are processing both steel and brass. The distributor for Affolter Technologies in the United States is Rotec Tools Ltd. (Mahopac, NY).

https://youtu.be/jD8TE1CCP80

Rotec Tools Ltd., 100 Buckshollow Road, Unit 3, Lemcar Industrial Park, Mahopac, NY 10541, 845-621-9100, Fax: 845-621-9102, i[email protected], www.rotectools.com.