The Next Step in Precision Tube Bending

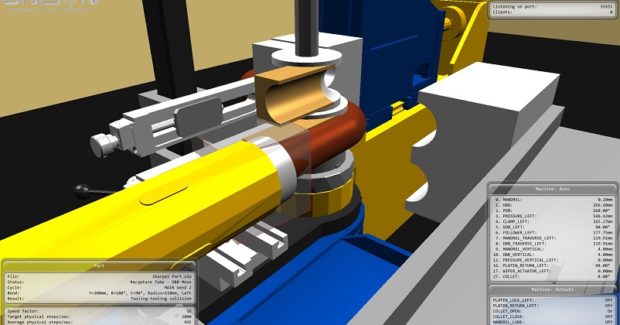

The Opt2Sim tube bending machine simulator from Unison accelerates the generation of error-free programs for bending tubular parts and includes powerful collision detection capabilities that can be used to avoid and verify a wider range of problem scenarios.

Posted: February 9, 2018

Unison Tube LLC (Asheville NC), a pioneer in all-electric CNC tube bending technology, offers advanced software to manage the tube bending process from programming to production in three areas: simulation, machine programming flexibility, and data collection that optimizes the versatility of tube bending and helps tubular part manufacturers substantially boost the productivity of their operations. The first element of the software is Opt2Sim, a 3D modeling simulator that accelerates the development of control programs for all-electric tube bending machines. This simulator employs the same embedded code that the tube bending machine runs on, ensuring that the simulator always performs in exactly the same manner as the machine, even as new machine control software features are added. Opt2Sim also simulates the bending of square and rectangular tubular profiles for further application versatility.

Opt2Sim enables fully validated bending programs to be created entirely off-line and is suitable for any machine in the Breeze range of all-electric tube benders. It incorporates a completely re-engineered collision detection utility that substantially simplifies a time-consuming task faced by users. This utility can be used to avoid and verify a wider range of problem scenarios, including collisions between tube and machine, tube and tooling, tube and the surrounding environment, or the tube hitting itself. In this iteration of the software, the user is even able to select the exact position he/she would like to view any collision, to make problems easy to understand and resolve.

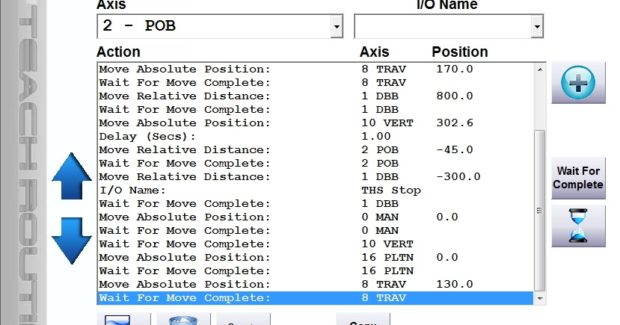

The second major element of the software is Unibend machine programming and control that features significant speed enhancements to both the bending and material handling elements of tubular part programs. The bend cycle software improves speed by some 5 percent. There is also a TEACH facility that gives users unprecedented access to the underlying machine code for handling parts, effectively allowing machine operation to be micro-managed for additional efficiencies. All a user needs to do is right-click on the relevant part of any program and the underlying code is presented in an easy to understand and editable form, allowing rapid changes to be made. The TEACH feature can be exploited in many ways, such as optimizing speed of operation by controlling individual and multiple axis movements, including the use of synchronized, parallel movements of multiple axes.

Or the facility can be used to slow movement, decreasing axis speed or inserting pauses or stops. In this way, users can fine-tune the standard bending and machine control sequences that the software generates to create highly optimized bending programs. For example, the feature might be used to allow inspection at an interim stage to slow movements to dampen vibration, to better handle lighter or heavier parts, to position the carriage to simplify unloading, or in many other ways. These features have been used to shorten the cycle time for complex multi-bend tubular parts by nearly 20 percent. Unibend provides much finer control over the profile motion of the important carriage feed and follower axes. Users can choose to use up to ten different movement speeds at as many as ten different points on any bend, providing immense flexibility to optimize bending programs for difficult materials and bend shapes. This feature is of particular help for users bending tubes to very tight radii, such as 1D (one diameter of the tube). Such tight bending has become increasingly important in many sectors where there is a growing need to save weight or space, while still maintaining a high integrity tubing structure.

The third software element is a database and data collection package that can be used in conjunction with the control system’s Ethernet compatibility to provide detailed information on machine usage. This package collects, stores and transmits comprehensive information on machine usage, such as detailed information on machine actions, including start and stop times of bend sequences, the part and batch being worked on. It also collects machine diagnostics information, including any error notifications, alarms, emergency stops, etc. This information is made available over the Ethernet network for local and remote monitoring, and for connection to a shop’s material requirements planning (MRP) software. A shop supervisor can monitor tube bending production in real-time, seeing what bending program is being used by any machine, the speed at which parts are being produced, etc.

Higher level management can use this package to generate reports showing information, such as progress with batches and orders, reports showing total output, machine and operator productivity, etc. “All-electric tube bending machines have been around for a couple of decades and have opened up a new world of higher productivity for many different types of manufacturing enterprises,” said Alan Pickering, the joint managing director of Unison. “The flexibility of the associated software utilities for programming, operating and managing machines represents the next frontier for progress, and these three elements are laying the foundations for further step-change increases in tube bending productivity.”

Unison Tube LLC, 28 Schenck Parkway, Suite 200, Asheville, NC 28803, 828-771-0850, [email protected], www.unisonltd.com.