Machining Turbine Shafts for Gas Power Plants

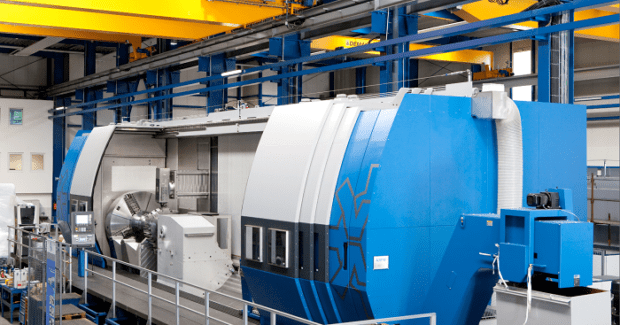

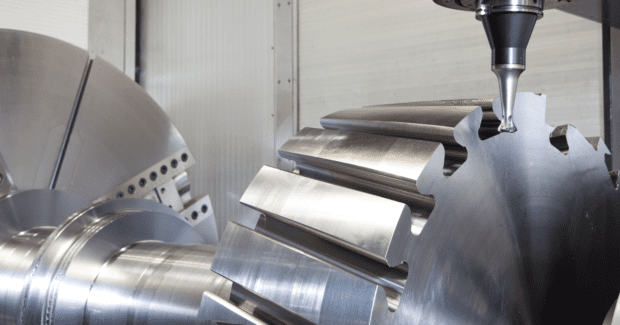

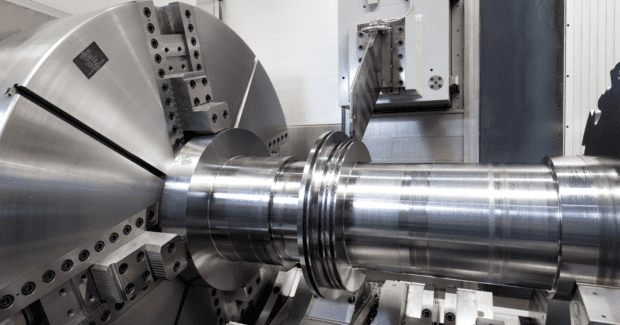

The mpmc 2000S machining center from Weingärtner reduces machining time by two-thirds on giant turbine shafts that are 2 m diameter, weigh up to 60 tons and feature innovative component geometries used in gas or vapor turbine power plants.

Posted: February 15, 2018

An American power engineering group uses a giant mpmc 2000S-7000 machining center from Weingärtner Maschinenbau GmbH (Kirchham, Austria) with tooling from Ceratizit (Reutte, Austria) for complete machining of workpieces weighing up to 60 tons. They have reduced the machining time by two-thirds for these enormous turbine shafts, which feature an innovative component geometry used in gas or vapor turbine power plants. The machine has a swing diameter over the bed and carriage is 2 m (78.74 in). Its maximum turning length (including 1 m (39.37 in) front machining) is 7 m (275.591 in). The 72 kW main spindle has a holding torque moment B-axis clamping of 20,000 Nm. The specifications for the turn-milling head are 72 kW / 3,000 min-1 / 1,950 Nm, and for the high speed milling head are 25 kW / 6,000 min-1 / 200 Nm.

Weingärtner Maschinenbau GmbH, Kirchham 29, 4656 Kirchham bei Vorchdorf, Austria, +43 7619 21030, www.weingartner.com.