Cost Effective Brazing of Light, Thin Section Parts Used in Power Generation

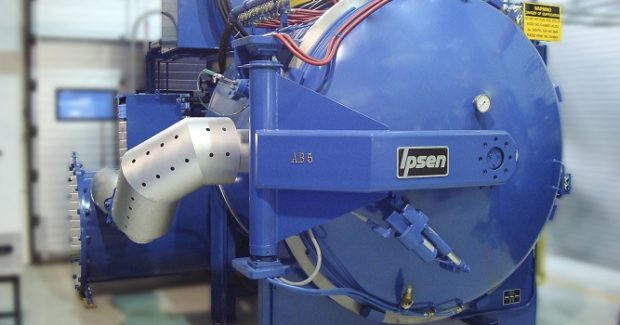

The horizontal-loading MetalMaster vacuum furnace with 2-bar gas quenching from Ipsen features a 36 in x 36 in x 72 in graphite work zone with a carbon steel gas distribution plenum and graphite heating elements, as well as a 3,000 lb load capacity.

Posted: February 12, 2018

A fabricator in the Southwest U.S. that manufactures catalytic converter products for power generation applications uses a horizontal-loading MetalMaster® vacuum furnace with 2-bar gas quenching from Ipsen USA (Cherry Valley, IL) that is well suited for brazing and other high vacuum applications. This customized vacuum furnace performs distinctively well with thin section parts and lighter pieces and features a 36 in x 36 in x 72 in (914 mm x 914 mm x 1,829 mm) graphite work zone with a carbon steel gas distribution plenum and graphite heating elements, as well as a 3,000 lb (1,361 kg) load capacity. It operates at temperatures of 1,000 deg F to 2,400 deg F (538 deg C to 1,316 deg C) with ±5 deg F (±3 deg C) temperature uniformity. The furnace is also equipped with a 35 in diffusion pump and a CompuVac® controls system.

This MetalMaster furnace is capable of meeting applicable AMS 2750E requirements and providing tight temperature tolerances with DigiTrim® controls settings. It also features an open heating element detection system and offers a specially engineered heat exchanger and turbine blower that are designed to optimize gas flow for more efficient cooling. This furnace design maintains ultimate performance and reliability, and delivers cleanliness and uniform cooling while also providing a cost effective, versatile and adaptable vacuum furnace system. It can be ordered with several high productivity options, including specialized instrumentation, increased pumping capability and material handling systems.

Ipsen USA, 984 Ipsen Road, Cherry Valley, IL 61016, 815-332-4941, Fax: 815-332-4549, [email protected], www.ipsenusa.com/compucore.