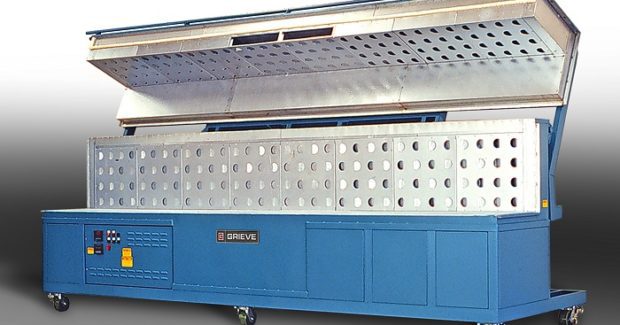

Top-Loading Oven for Testing Oil Field Downhole Equipment

No. 868 is a special 500 deg F high temperature top-loading oven from Grieve with an inside workspace of 185 in W x 18 in D x 24 in H that features 34.8 kW installed in Nichrome wire heating elements and two 2 hp recirculating blowers providing 4,000 CFM of total horizontal front to rear airflow.

Posted: January 2, 2018

No. 868 is a special 500 deg F (260 deg C) high temperature top-loading oven from Grieve Corporation (Round Lake, IL) that is currently used for testing oil field downhole equipment in the fabrication shop of a parts supplier. Workspace dimensions of this oven measure 185 in W x 18 in D x 24 in H. The oven features 34.8 kW installed in Nichrome wire heating elements, while two 2 hp recirculating blowers provide 4,000 CFM of total horizontal front to rear airflow. This special top-loading oven features 4 in insulated walls, aluminized steel interior and exterior, plus reinforced ¼ in steel plate workspace floor designed to hold 3,600 lb distributed load. The oven is supported on six swivel casters with swivel locks and brakes and has a motor-operated, rear-hinged door. Controls on No. 868 include a digital indicating temperature controller, a manual reset excess temperature controller with separate contactors and a recirculating blower airflow safety switch.

Grieve also offers the No. 835, a 1,200 deg F electrically-heated walk-in oven that is currently used for heat treating steel parts. The workspace inside this oven measures 48 in wide x 72 in deep x 72 in high and a maximum temperature of 1,200 deg F is provided by 120 kW power installed in Incoloy-sheathed tubular heating elements. A 10,000 CFM, 7½ hp recirculating blower provides combination vertical/horizontal airflow to the load. This oven features an aluminized steel exterior, 16 ga stainless steel interior and 10 in thick insulated walls, comprising 2 in of 1,900 deg F block and 8 in of 10 lb density rockwool insulation, as well as a 7 in insulated floor with integral truck wheel guide tracks. Safety and control equipment on this oven include a 325 CFM-powered forced exhauster, digital indicating temperature controller, manual reset excess temperature controller with separate contactors, recirculating blower airflow safety switch, and a 4-pen circular chart recorder.

Grieve Corporation, 500 Hart Road, Round Lake, IL 60073-2835, 847-546-8225, Fax: 847-546-9210, [email protected], www.grievecorp.com.