Multi-Tasking Productivity in Machining Large Parts for Oil and Gas

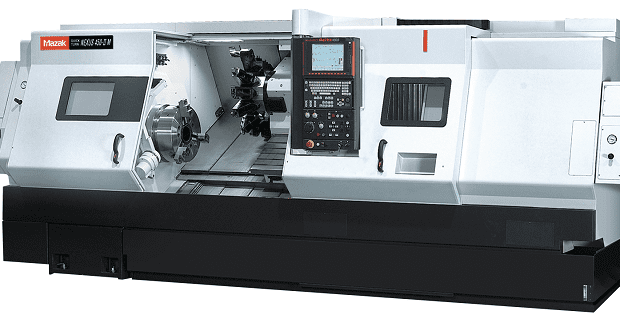

The multi-tasking QTN 450M turning center from Mazak performs milling, drilling and tapping operations for highly efficient single-setup part processing to boost productivity and reduce cycle times when machining large diameter, shaft-type parts used in oil and gas.

Posted: January 17, 2018

Mazak Corporation (Florence, KY) offers their QTN 450M turning center with multi-tasking Done In One® capabilities that boost productivity and reduce cycle times for large diameter, shaft-type part used in oil and gas. This turning center provides high performance and value via its single setup turning and milling operations that allow for improved throughput. The machine sports a 457 mm (18 in) chuck mounted on a 50 hp, 2,000 rpm integrated spindle motor on the main turning spindle for heavy duty metal removal. The spindle is a full function, CNC-controlled C-axis for milling that indexes at 0.0001 deg increments to accurately position parts for square facing and slotting cuts, as well as precisely drilled holes. With a 12-position drum turret and 10 hp, 4,000 rpm rotary tool spindle, the QTN 450M performs milling, drilling and tapping operations for highly efficient single-setup part processing.

Mazak also offers the HCN-4000 horizontal machining center with enhanced multi-tasking, high precision honing and orbital machining capabilities that are especially beneficial for milling, boring and honing pump housings and valve-type components for mud pumps, frac pumps and other equipment used in oil fields.

Key machine features of the HCN-4000 include fast rapid traverse speeds and acceleration rates as well as short chip-to-chip times that all contribute to reductions in overall part cycle times. The machine rapid traverses at speeds up to 2,362 ipm (60 m/min) and accelerates at 1G in all axes. Spindle acceleration speed is only 1.3 seconds for the machine’s standard 12,000 rpm spindle and 1.5 seconds for its other optional spindles. Spindle options of 14,000 rpm, 18,000 rpm and 30,000 rpm are available for speed, efficiency and versatility when machining a wide variety of materials from steels to nonferrous metals. Four available integral motor spindle types – standard, high torque, semi-high speed or high-speed – allow users to match spindle performance to their specific machining requirements with the proper speeds and power.

The standard 40-taper 12,000 rpm spindle provides power and speed for general machining applications, while the high torque, heavy duty 40-taper 14,000 rpm version generates 88 ft-lb of torque at a continuous rating to a maximum of 223 ft-lb to increase metal removal rates for hard-to-machine materials. With maximum speeds of 18,000 rpm and 30,000 rpm, the 40-taper semi-high speed and HSK high speed versions allow for faster machining and superior surface finishes when cutting aluminum and other nonferrous workpieces. The HCN-4000 is equipped with a standard 40-position tool storage magazine and optional 60-, 80-, 120- and 160-postion magazines in addition to Tool Hive magazines with either 180, 240 or 330 positions. The large tool storage capacity of this HMC enables shops to handle a wide variety of parts and perform continuous unattended machining over long periods of time.

The machine’s MAZATROL Smooth G CNC makes it easy to generate programs for processing complex parts. The control incorporates a wide variety of advanced programming functions that allow it to offer complete ease of use and ensure high-speed, high-accuracy machining performance. Functions of the control include High Gain Feed Forward Control that boosts machining speed and accuracy, Variable Acceleration Control to calculate optimal acceleration for a combination of axes, Intelligent Pocket Milling that engages a high efficiency toolpath when milling part cavities, and Smooth Corner Control to make cutter path adjustments to help shorten cycle times; and many more.

The Smooth Orbiturn function makes both honing and orbital machining possible of round and eccentric features on large, odd-shaped parts such as valves and manifolds while the components remain stationary. Mazak worked with honing system leader Sunnen Products Co. (St. Louis, MO) to develop the special hone tooling needed for horizontal machining center integration. In the application, controlled high pressure fluid transfers through the machine’s spindle into the toolholder and to the Sunnen honing tool to position and adjust its abrasive pads/stones. The system then provides closed-loop feedback as to hole ID size for in-process adjustments.

For shops that are ready to ramp up production with advanced automation, the HCN-4000 easily incorporates into the highly flexible PALLETECH System that is controlled with Smooth PMC software and configures into one, two or three levels for completely automated and continuous production cells that also accommodate different types of Mazak machine tools so that shops can mix and match machine types, such as horizontal machining centers together with vertical machining centers, for processing versatility. Smooth PMC cell control software efficiently manages and maximizes PALLETECH System operations, allowing users to look ahead with production simulations to forecast needed tools, machine loads and output levels for up to a week’s worth of scheduled cell workflow. It also allows for advanced PALLETECH cell connectivity, analytics and performance data outputs in graphical formats via a smart phone.

Mazak also offers the innovative double-column, quill-head HCN-16000Q horizontal machining center that performs the operations of both an HMC and a traditional boring machine to significantly improve its part processing flexibility and reduce part setup to improve overall throughput. This machine is available in single table (open or covered) and two-pallet machine configurations and can be added to existing manufacturing cells, including those with dissimilar machines such as the e-Vertical and INTEGREX series of machines. When the HCN-16000Q is part of an automated PALLETECH cell, it further increases the cell’s overall Done In One processing versatility with the addition of deep boring and U-axis machining capabilities.

For stability, reliability and accuracy, the double-column design centers the quill head to eliminate potential problems resulting from overhang or imbalance that are typically associated with traditional boring machines. The double column also features a twin ballscrew-driven Y-axis that does away with the need for any type of counterbalance mechanism and ensures fast, precise and smooth Y-axis stroke extension and retraction. The quill features a built-in motor, high torque, direct drive 50 hp (37 kW) spindle that puts out 1000 ft-lb (1,357 Nm) of torque. The quill is equipped with linear drive guides as well as both angular contact and roller-type bearings. Roller bearings in the front of the spindle provide stability against strong side forces from face milling or heavy roughing, while the angular contact bearings in the back support the quill’s Z-axis thrust for heavy duty boring and drilling operations.

Standard tool capacity of the HCN-16000Q is 80 tools, with options to increase that to 120 or 160 or incorporate the TOOLTECH system. Also available is a tool changing system specifically for handling larger sized tools. The changer mounts to the machine’s pallet changer and quickly moves larger size tools in and out of the machine to speed exchanges and reduce non-cut times. This machining center is also offered with an automatic attachment changer that further boosts part processing flexibility through the use of various special operation attachments such as angled heads, U-axis boring tools and facing heads, U-axis OD turning heads and snout heads. The 49.2 in x 63.0 in (1,250 mm x 1,600 mm) pallets in the HCN-16000Q accommodate parts up to 118.11 in (3,000 mm) diameter, 78.74 in (2,000 mm) high and weighing as much as 17,636 lb (8,000 kg) (two-PC model) and 22,046 lb (10,000 kg) (single table model). Machine axis travels measure 110.236 in (2,800 mm) X, 63 in (1,600 mm) Y, and 72.834 in (1,850 mm) Z, while the quill W-axis feed stroke is 21.653 in (550 mm).

Mazak Corporation, 8025 Production Drive, PO Box 970, Florence, KY 41042, 859-342-1700, Fax: 859-342-1865, www.mazakusa.com.