How to Achieve Maximum Tool Life with Proper Maintenance

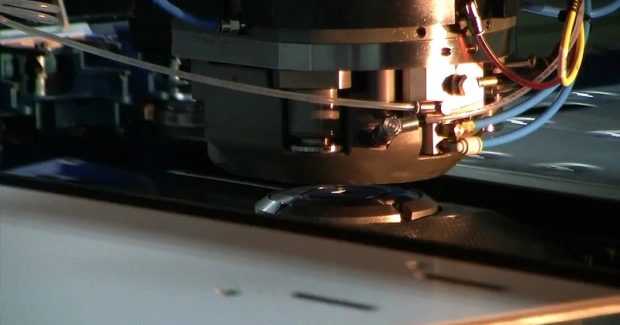

Want to make the most out of your investment in punch press tooling and also help ensure the longevity of your machines? Here are a few simple maintenance recommendations to follow.

Posted: January 10, 2018

Quality punch press tooling is a significant investment for any machine shop. Without proper maintenance, the precision and life of your tooling can suffer, resulting in poor quality parts, higher tool replacement costs and lower productivity. By following a few simple maintenance recommendations, you can make the most of your investment and help ensure the longevity of your tooling and machines.

WHY KEEP TOOLS SHARP?

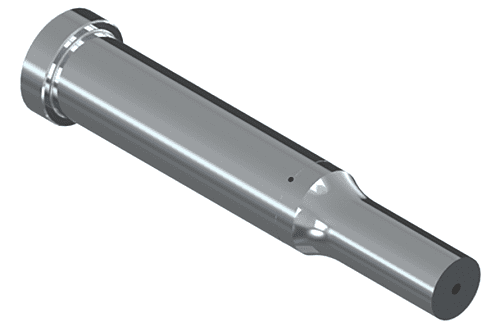

Regular tool sharpening is essential to consistently producing quality parts. When sharpening is neglected, the punching edge of the tool breaks down more quickly. Dull punching tools can create problems like excessive burrs, material waste, increased tonnage, tool chipping, breakage and stripping problems. This will affect the quality of your parts, increase tooling costs and reduce production performance. Sharpening tooling regularly by small amounts ensures that the machine and tooling will last longer.

PRACTICE PROPER SHARPENING

Be On Time. When it comes to tool sharpening, timing is everything. A good rule of thumb is to grind less but sharpen more often. Intervals between regrinds vary widely depending on the material type and thickness being punched. And, of course, the level of tool usage is the primary influence on the wear of a tool. That being said, tools used for slitting and nibbling typically will need sharpening more frequently due to frequency of use. One of the first indicators of dull tooling is seeing excessive burrs on your part. A burr is a sharp protrusion or thin ridge of roughness remaining on sheet metal as a result of the cutting operation. Also, listen to the machine: if the punch press is making more noise than usual when punching with a particular tool, that tool’s cutting edge may be dull. Generally, a tool needs to be sharpened when the radius that forms on the cutting edge is worn to between .004 in (0.1 mm) and .010 in (0.25 mm).

Do It Right. A bad sharpening process can be more detrimental to the tool than using it dull. There are two basic methods for sharpening punch press tooling: one is to use a manual surface grinder and the other is to use an automated sharpening grinder. Regardless of which style you use, it is important to have these good practices in place when sharpening:

- Make sure the tool is securely loaded and clamped in a suitable fixture to minimize vibration and chatter.

- Ensure the wheel is clean and dressed to present a flat grinding surface.

- Always provide a good flow of coolant to the wheel and tool to keep it cool and remove the grinding swarf.

- Use the proper vertical and horizontal feed rates – removal of too much material per pass may cause the metal to overheat, resulting in surface cracking. Light, frequent passes should be taken – typically, removing no more than .0005 in (0.01 mm) vertically per pass while moving horizontally on the punch or die face is recommended.

For the most consistent grinding results, consider using an automated sharpening grinder for punches and dies. Automated grinders provide a superior finish and save time because most of the grinding best practices listed above are designed into the way the machine itself operates.

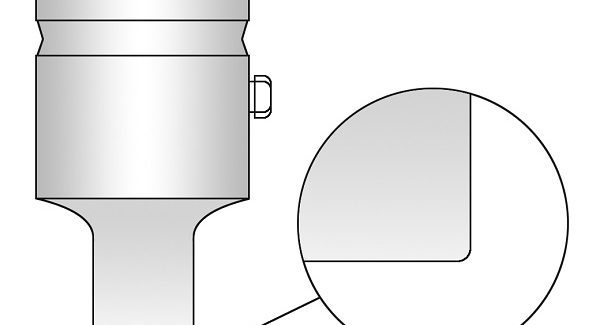

Don’t Forget the Die. Some machine shops may have a tendency to focus primarily on the condition of the punch, but they will run a die until it breaks or barely functions. For the best punching results, dies must be maintained as well. A dull die will have a negative effect on the punch life and produce poor results. Never sharpen a die beyond the manufacturer’s recommendations. Dies are designed with a specific amount of die land, which is reduced each time you sharpen. If you over-grind your dies it can promote slug pulling. Lastly, it is important to shim dies to the right height to maintain proper die penetration.

Regularly Check Machine Alignment. Proper alignment of machine tool stations is critical to maximizing tool life. If turret alignment is off, then the die clearance is not maintained around the circumference of the die aperture. This will cause burrs, parting nibble marks and premature tool wear. Station misalignment will be evident by uneven tool wear and inconsistent burr size. To realign the station, adjust the lower die shoe. This can be done by the machine owner, but requires special alignment tools that can be purchased from the OEM or most tooling suppliers. Another important way to help ensure good tool alignment is to use high quality precision tooling.

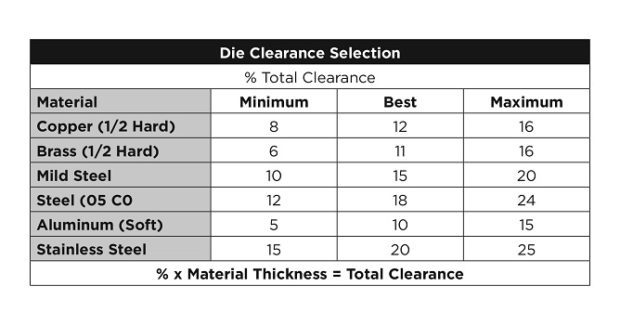

Use Correct Die Clearance. Having the proper die clearance is a critical part of the punching process that directly impacts part quality and punch life. If die clearance is too small, symptoms include premature tool wear and galling. If die clearance is too big, slug pulling may result, including excessive burrs. Either way, incorrect die clearance results in poor part quality, extra labor, more scrap and higher tool replacement costs. There is no one-size-fits-all solution to determining the appropriate die clearance. The correct amount of clearance is variable based on material type and thickness. Please reference the nearby chart that lists some guidelines. If you need more information, contact your tooling supplier so that they can help you determine the proper clearance for your particular application.

In addition to the maintenance recommendations outlined here, other options to maximize the life of your punch press tooling include considering the design of the tool itself or choosing high quality tool steels, coatings or custom heat treatments.