Economical Processing of Sheet and Plate Material

Advanced laser cutting systems and press brakes from Bystronic can process brass up to 5/8 in thick, mild steel up to one inch thick, and aluminum and stainless up to 1.180 in thick, all with impressive quality and precision to the outermost edges of the metal sheet.

Posted: January 1, 2018

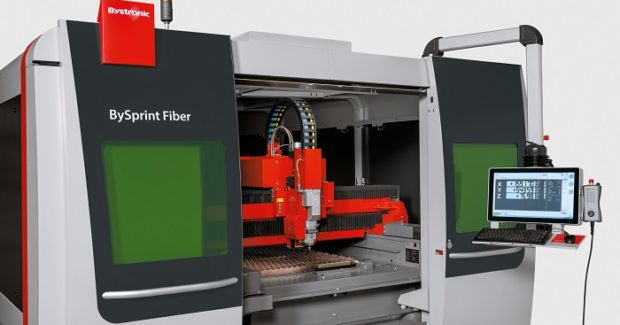

The BySprint Fiber laser cutting system from Bystronic Inc. (Elgin, IL) expands the basic version of the machine with an extended performance package and a new, fundamentally revamped design that is distinguished by its dynamic lines and a larger operator touch screen panel. The system also includes three powerful additional functions – Detection Eye, Power Cut and Observer – for more performance at no additional cost. Detection Eye supports users during cutting preparations by using a camera system on the cutting bridge that recognizes the precise position of the loaded metal sheet in just a few seconds. This automatic edge detection allows set-up time to be reduced by up to 17 seconds with every sheet. This high precision measurement also ensures precise cutting to the outermost edges of the metal sheet.

Power Cut increases the cutting spectrum of the 6 kW version of the BySprint Fiber by enabling extremely fine cutting quality on sheet metal up to 1.180 in thick. Power Cut Fiber also increases the range of thicknesses that can be processed with applications in non-ferrous metals, aluminum, and mild steel. When equipped with Power Cut Fiber, the BySprint Fiber can cut brass up to a thickness of 5/8 in, mild steel up to one inch, and aluminum and stainless up to 1.180 in, all with impressive quality. The Observer is a camera-supported remote monitoring system that provides users with a direct link to the BySprint Fiber by using web-enabled devices, such as notebooks, tablets, and smartphones to access information about the production processes of the machine, regardless of time and location. Information is provided that allows orders to be calculated reliably and efficiently to minimize unscheduled idle times and reduce deviations from the planned time per part.

The BySprint Fiber is available in 3015, 4020, 6520 and 12020 formats, including a Fiber 3000, Fiber 4000 or Fiber 6000 laser source. The higher power considerably increases cutting speed in the thin to medium range sheet metal thickness. Depending on the type of material and the sheet thickness, parts output can be increased by up to 400 percent. Equipped with a ByTrans Extended automated material loading and unloading system, the 3015 and 4020 models can generate highly productive and efficient job flows with significant energy savings and low operating and maintenance costs.

Bystronic also offers their affordable Xact Smart press brake with advanced features that are easy to set up and program for high bend accuracy. Bysoft 7 software integrates this press brake seamlessly into the production environment. A powerful ByVision Bending control system interface uses a full 22 in HD touch screen to display realistic 3D part processing animations, simulation of bending cycles and collision monitoring, and software-driven menu selections that guide operators step-by-step through the bending process, as well as automatically selecting bend sequences. It has an extensive database that includes parameters for all of the common types of sheet metal and bending tools. The user interface factors in the material thickness and bending angle to determine the ideal bending process and suggest suitable tools. Standard hydraulic crowning capabilities deliver accurate bend angles across the entire bed length to ensure a high degree of air bending accuracy. Programming is simple and intuitive, from the order to finished part.

Xact Smart is available in several models with capacities between 50 tons and 300 tons and up to four axes on the backgauge which, depending on the combination, can process simple angles through complex bent parts. This press brake offers a high level of flexibility for fast job changes and can also be used as a fixed bending station. A wide selection of Bystronic bending tools can be set up in a few simple steps using the optional RF-A Pro fast clamping system. Using the optional XPT Pro clamping system, tools from third-party manufacturers can also be used with the Xact Smart. Other benefits include an ergonomic LED workspace lighting and laser safety system.

https://youtu.be/HGmq9RpwvEU

Bystronic Inc., 200 Airport Road, Elgin, IL 60123, 847-214-0300, [email protected], www.bystronicusa.com.