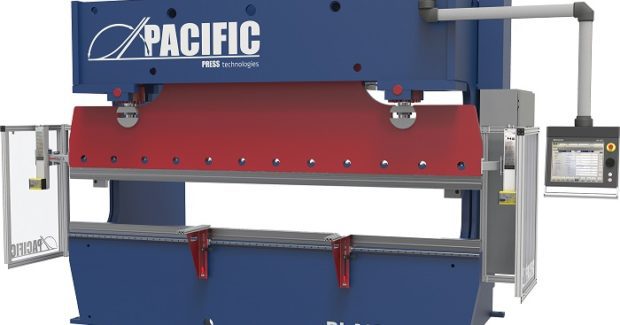

Configurable, Low-Tonnage Servo-Hydraulic Press Brakes

Configurable, low-tonnage servo-hydraulic Blaise press brakes from Pacific Press deliver exacting bend tolerances and rugged reliability, using trunnion-mounted cylinders for longer, more accurate bends up to the full length of the ram and a two-stage ram drop speed to reduce bending time and shorten higher-quantity runs.

Posted: January 2, 2018

Pacific Press Technologies (Mt. Carmel, IL), a subsidiary of Right Lane Industries LLC (Chicago, IL), offers the Blaise family of configurable, low-tonnage servo-hydraulic press brakes that deliver exacting bend tolerances and rugged reliability. These press brake feature modular, lubeless gibbing assembly for low maintenance, worry-free operations and dramatically less downtime. They use trunnion-mounted cylinders for longer, more accurate bends up to the full length of the ram. They use a two-stage ram drop speed to reduce bending time and shorten higher-quantity runs, with standard tooling attachments and quick-change tooling compatibility that accommodates changing needs as manufacturing processes improve. A 3D Delem CNC controller on an 180 deg pendant arm lets users work efficiently, with no more wasted time walking back and forth from bend point to controls. A multi-axis back gauge (up to five axes) enhances the reproducibility and efficiency of production runs. These press brakes offer the longest frame warranty in the industry.

https://www.facebook.com/pacificpresstech/videos/1950743045174686/

Pacific Press Technologies, 714 North Walnut Street, Mt Carmel, IL 62863, 618-262-8666, www.pacific-press.com.