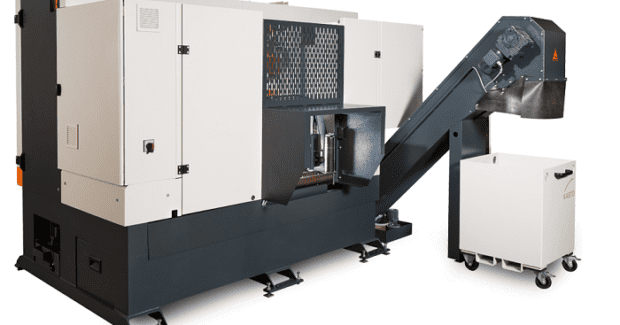

Automatic Band Saws for High Cutting Performance with Low Material and Energy Consumption

Fully automatic KASTOwin band saws from KASTO are ideal for flexible production sawing of solid materials, tubes and profiles used in mechanical engineering, toolmaking, steel, automotive and aerospace work.

Posted: January 1, 2018

Five fully automatic KASTOwin automatic band saw models from KASTO, Inc. (Export, PA) are all built in Germany to the same design, using substantially identical components that create a comprehensive range of efficient standard equipment that provides excellent value for the money. By reducing material and manufacturing costs, KASTO can offer these saws at a significantly more attractive price than comparable machines from other manufacturers. Combining high cutting performance with low idle times, KASTOwin A 3.3, A 4.6, A 5.6, A 8.6 and A 10.6 automatic band saws are ideal for flexible and universal production sawing of solid materials, tubes and profiles. These band saws cover a cutting range from 330 mm to 1,060 mm and are suitable for use with different steels, including those used in the mechanical engineering of oil and gas construction.

The torsionally rigid upper section of the band saw provides greater vibration damping than conventional cast iron structures. The other housing components are made from robust steel that enables the saw blade to run quietly and produce better sawing accuracy. The vice and saw feed are equipped with zero-play linear guides. Ball screw spindle drives ensure controlled cutting and material feed movements that achieve a cutting accuracy of ±0.1 mm over a 100 mm cutting length at cutting speeds of up to 150 m/min. Maximum cutting performance is assisted by the easy-to-operate SmartControl sawing machine controller that contains all the material data and automatically sets all the necessary parameters. The KASTOrespond system that was developed specially for this range continuously records the forces at the tool and uses an intelligent algorithm to convert these into feed movements.

With a residual length of only 35 mm (60 mm for Model A 3.3), KASTOwin saws make optimum use of the material. They combine hydraulically pre-tensioned saw blade guides with vibration-damping return blade guides that extend saw blade lives up to 200,000 cm². A highly efficient, frequency-controlled drive and a compact hydraulic power pack that only runs on demand ensure that the saw uses as little energy as possible to reduce operating costs. For special requirements, a large range of accessories are provided to configure these saws to any application, including a laser for projecting the cutting line, a minimum quantity lubrication system, a chip conveyor in spiral design, and roller conveyors in various designs on the feed and discharge sides. The saws are available on request with a performance pack with double chip removal brush and greater drive power, or with a heating pack with special hydraulic oil, coolant and electrical cabinet heating.

Options for special systems are available with the KASTOwin F, such as bundle clamping devices and extended material feed systems. There are also different feed systems, such as double roller conveyors, inclined magazines and chain magazines, depending on the machine size. To dramatically reduce idle times on these saws, KASTO can connect them to sophisticated material handling and storage systems for sheet metal and bar stock, such as their modular UNITOWER tower storage system that is available in three different design modules: UNITOWER for the storage of bar materials, UNITOWER B for sheet metal, flat products and containers, and the compact UNITOWER C universal store for bars and sheets. UNITOWER is available as a single or double tower, optionally freestanding in a workshop or as a separate storage building outside with ceiling and wall elements. Any number of input and output stations can be positioned at the front or on the long side of the storage tower and at different levels, depending on the shop’s requirements.

Cassettes, pallets or supporting frames are used as the load carriers. Depending on the design, each storage space can carry loads of up to five tons. These towers effortlessly accept bar stock from 3,400 mm to 14,600 mm long, giving shops recourse to different standard lengths along with part- or production-optimized special lengths. The basic version of the UNITOWER has a usable width between 600 mm and 1,240 mm that can be matched ideally to available floor space. UNITOWER B stores sheet metal and flat products in lengths between 2,000 mm and 8,000 mm. The usable width is between 1,000 mm and 2,000 mm. The loading height and number of storage spaces can be determined as needed to accommodate pallets, boxes or containers. System heights up to 25 m can be easily achieved with the UNITOWER and UNITOWER B. With their variable loading height, these flexible tower storage systems save more space and are more economical than conventional floor and cantilever arm storage systems.

The cost effective, standardized UNITOWER C compact storage system for different bar and sheet formats has a maximum height of 7,200 mm with flexible compartment distribution that is ideal for small businesses, workshops, maintenance shops and as a buffer store between production areas. Two versions are available: as a storage system for flat goods with a usable width and length of 1,524 mm x 3,048 mm and loads between one and three tons, or as a storage system for bar stock accommodating cassettes with dimensions 840 mm x 6,500 mm and loads between 0.8 tons and 2.5 tons. Along with the low space requirement, UNITOWER storage systems are distinguished by high efficiency. A storage and retrieval machine (SRM) with spreader beam handles the load carriers. It is not necessary to move the entire stock, only the relevant cassette, ensuring rapid access times and – thanks to efficient drives – saving energy. Input and output stations can also be connected to other conveyor equipment or processing machines to optimize the internal material flow.

https://youtu.be/jmrp6alpPc4

Depending on the model, the tower storage system is controlled by EasyControl and BasicControl semi-automatic or fully automatic controllers that can be operated easily and intuitively by means of a graphical interface. The user calls up and controls various functions, such as storage compartment and cassette management, order expediting and system diagnostics using the touch screen. High system availability is ensured by round-the-clock telephone advice, a rapid supply of spare parts, competent on-site support and remote monitoring via the Internet by technicians to find and rectify faults at an early stage before they lead to costly system failures.

KASTO, Inc., 3002 Venture Court, Export, PA 15632-8949, 724-325-5600, www.kasto.com.