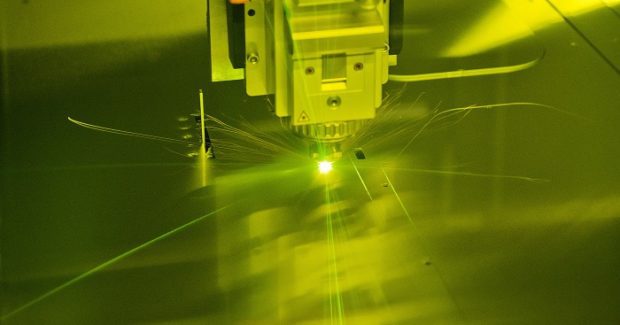

Ultra-High Speed Fiber Laser Cutting for Trailer Body Manufacturers

The Electra FL 3015 8 kW fiber laser cutting machine from LVD Strippit maintains 2G acceleration while cutting to produce high quality, high accuracy cuts in simple to complex configurations on ferrous and non-ferrous materials.

Posted: December 7, 2017

LVD Strippit, Inc. (Akron, NY) offers their ultra-high speed Electra FL 3015 8 kW fiber laser cutting machine that cuts a wide range of ferrous and non-ferrous materials as fast as the thermal process allows without dynamic compromise. The Electra 8 kW can maintain 2G acceleration speed while cutting, producing high quality, high accuracy cuts in simple to complex configurations. It features a new, advanced cutting head with automated adjustment of focus position and focus diameter (zoom focus). Zoom focus control can dramatically improve piercing times, cutting speeds and cut performance in all material types and thicknesses, increase throughput and reduce the need for operator intervention. The ability to change the focal point allows Electra to pierce 20 mm material in just two seconds for significant productivity on fully nested sheets. This also means that less heat is generated in the material, making it more efficient to cut small holes.

A new “smooth lead-in” feature guarantees a much faster but stable lead-in after fast piercing when cutting thicker material (greater than ¼ in, 6 mm) with nitrogen, resulting in an average gain of up to 15 percent on part cutting times. A linear drive system harnesses the full benefits of the higher power cutting capability of the 8 kW fiber laser. Electra’s high cutting dynamics and rapid acceleration achieve high part output. The machine’s rigid frame design ensures that cutting performance is reliable at top cutting speeds. The rigidity of the mono-frame construction also means no foundation is required. The laser source has a high wall plug efficiency of up to 40 percent for savings in electrical operating costs. This machine features the latest generation 19 in Touch screen graphical interface, making the system easy to operate for virtually any level of user. An icon-driven user interface guides the operator through all necessary man-machine interactions, making machine setup fast and uncomplicated.

Electra offers two levels of automation: an automated load/unload system (FA-L) to keep pace with the machine’s high cutting speed, or a Compact Tower (CT-L) with full capabilities for loading, unloading and storage of raw materials and finished parts. To keep up with the speed of the fiber laser cutting system, the Dyna-Press electric-drive press brake delivers fast bending speeds of 59 ipm to bend more parts per hour at a lower cost per part. Its ergonomic design permits use in a standing or seated position. It provides impressive production capabilities, an easy to use control and compact size for a press brake that is fast, accurate and flexible. The Dyna-Press 40/15 Plus, a 40 ton model, has a working length of 60 in and features a precision four-axis back gauge and the exclusive TOUCH-B touch screen CNC control.

Speaking of control, the new CADMAN® Suite version 8.5 of programming and shop management software from LVD Strippit includes enhancements for every CADMAN module in the integrated suite of software products, features an improved dashboard for more intuitive use, and extends the suite’s integration capabilities to include the next generation of LVD Strippit Touch-P punch press control, as well as non-LVD sheet metal fabrication equipment. This software suite helps streamline the complete fabrication process to make smart manufacturing possible, starting with a 3D part concept, communication to production control, organizing a shop’s manufacturing flow, to cutting, sorting and bending. Beyond its new, modern look and feel, v8.5 provides these key updates:

- CADMAN-B bend CAM software has improved bend solution finding, including tool preselection based on active catalog(s) and preferred (custom) tooling that can be selected, followed by several checks ending with a collision check on a 3D virtual production. The intelligent import function for import part by part or in batch has been enhanced. Form features are recognized, existing bends in the part can be indicated, or bends can be excluded from the automatic solution find process.

- CADMAN-B is now available for Synchro-Form Series press brakes with the next generation of adaptive bending systems designed specifically for bending XXL profiles.

- CADMAN-L and CADMAN-P CAD/CAM software modules feature advanced nesting capabilities for laser cutting and punching. New functions such as “minimal heat impact” while finishing parts one by one, material thickness defined parameters, and material and material condition technology cutting tables ensure a more smooth and automatic preparation for laser cutting. For punching, smart functionality such as “avoid hits with form tools” and “punch with form tools last” ensure reliable punching preparation. In the common module, parts can be detected automatically or manually in a multiple part drawing.

- CADMAN-JOB now connects to the latest Touch-P control for LVD Strippit punch presses and integrates to other non-LVD fabrication cutting equipment. It connects the front office intakes and processing of orders with shop floor operations, facilitating a controlled process from the order to the finished part. The software provides real-time insights from the shop floor so that users can optimize machine production time and fabrication resources. The Touch-i4 tablet works as a companion to CADMAN-JOB and helps sort parts after cutting. It has the added functionality to assign parts to a certain location that can be an identified carrier or warehouse position.

- CADMAN-SDI, Smart Drawing Importer, makes generating accurate cost estimates from imported CAD files easier and more accurate with a greater number of built-in cost drivers that help fabricators identify what’s driving their indirect manufacturing costs to determine the true cost of a part/product. It also offers more functionality for file exporting and improved batch importing capability. Additional cost drivers, including the length of the longest bend and maximum required bend force, are now part of the information on the display or in the export file.

In all, the v8.5 updates make CADMAN Software Suite a more powerful tool to meet the digitally integrated needs of today’s manufacturing and Industry 4.0.

LVD Strippit, Inc., 12975 Clarence Center Road, Akron, NY 14001, 716-542-4511, Fax: 716-542-5957, [email protected], www.lvdgroup.com.