Plasma Beveling Gets Smart

The DMX Automated Plasma Beveller from ESAB cuts the full range of weld preparations, including V, Y, X, and K bevels, with cut angles up to 45 deg on materials up to 50 mm.

Posted: December 10, 2017

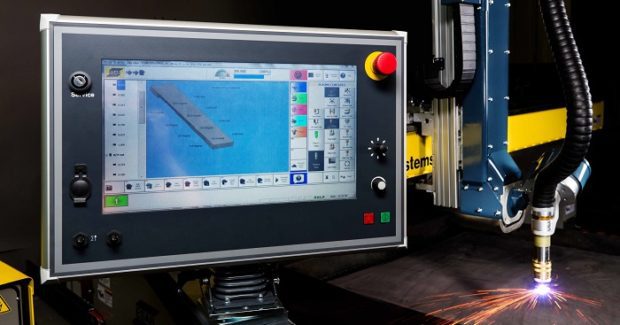

The DMX Automated Plasma Beveller from ESAB Welding & Cutting Products (Florence, SC) is a next-generation beveling system that delivers significant performance improvement through a simple, compact design. The DMX Beveller provides high reliability, enhanced safety and ease-of-use. It cuts the full range of weld preparations, including V, Y, X, and K bevels, with cut angles up to 45 deg on materials up to 50 mm. This system is complemented by the release of new SmartBevel™ Technology for easier programming and accurate bevel cutting with minimal operator intervention. SmartBevel includes beveling data and geometric compensations that are necessary to cut V, X, Y, and K bevels on mild steel from 6 mm to 50 mm thick. Unlike competitive systems, this technology integrates all bevel compensations into the CNC, so bevel programming is simplified, and any fine tuning of the cut is done quickly and easily at the machine.

ESAB uses a new approach to providing 5-axis motion, utilizing direct drive motors to radically reduce complexity, eliminate the need for breakaway crash protection, and deliver responsive, accurate positioning. The direct drive design eliminates gearboxes, belts, pulleys, limit switches and exposed cables. The resulting “compliant motion” lets the DMX Beveller absorb and detect a torch crash without any added components, as well as automatically reset after a collision without the operator touching the torch or climbing on the cutting table to do so. Faster resets result in higher productivity and eliminate dangerous operator tasks from the beveling process. The reduction in complexity afforded by direct drive technology enhances both performance and reliability, and enables an extremely compact design.

“Direct drive motor technology provides extremely accurate positioning with zero backlash, and it handles fast direction changes,” explained Steve Zlotnicki, a global product manager with ESAB Cutting Systems. “The design is so simple and robust that there is almost nothing that can go wrong.” Reducing the size and weight of the bevel head has additional advantages. The DMX Beveller is significantly smaller and lighter than traditional plasma bevel heads, so it can be mounted on smaller gantries, making quality plasma bevel cutting more affordable and saving valuable floor space. DMX is available on the Combirex DX and larger gantries.

The DMX Beveller also uses compound motion to provide beveling in any direction. This type of motion system has no rotation limit and thus eliminates the need to unwind the torch leads or pre-position the head, which further improves cycle time and productivity. It also extends torch life by not twisting the torch leads, but does so without using an expensive torch bearing. A Multi-Point Collision Protection System provides complete collision protection for the entire bevel head. Multiple sensors are used to protect parts of the bevel head that come in close proximity to the cutting table. The DMX Beveller also protects all hoses and cables from the harsh environment of plasma cutting. The head features a complete set of covers protecting all components, plus a fully enclosed cable chain to protect all hoses and cables. A robotic-style torch lead sheath protects the torch leads as well.

The DMX Beveller comes with a two-year limited warranty that covers defects in materials and workmanship for all major electrical and mechanical parts of the bevel head itself, including lift motor, lifter screw, lifter bearings and rails, bevel axis motors, crash switches, cables and connectors.

ESAB Welding & Cutting Products, PO Box 100545, 411 South Ebenezer Road, Florence, SC 29501-0545, 603-298-2259, Fax: 843-664-4258, www.esab.com.