Multi-Mode Feed Capability Increases Coil-Fed Laser Blanking Speeds

With Continuous Mode (On the Fly Cutting) capabilities on coil-fed laser blanking systems from LaserCoil Technologies, users can choose either Feed Index Mode (Stop/Start) or Continuous Mode for the best production run rate and reliability.

Posted: December 7, 2017

By applying laser blanking to sheet metal production for vehicles, no die is required and press hardening can be avoided, leading to higher design freedom, lower cost, and higher formability – the advantages of conventional press blanking. But because of its overwhelmingly slow process speed compared to press blanking, laser blanking is mostly used in low volume prototyping. Increasing laser blanking process speed is essential to maximize its advantage over press blanking, so LaserCoil Technologies LLC (Napoleon, OH) has added Continuous Mode (On the Fly Cutting) capability to their coil-fed laser blanking systems, enabling users to choose either Feed Index Mode (Stop/Start) or Continuous Mode in order to optimize cutting parameters for each part configuration, increasing processing rates and enhancing quality.

“The introduction of multiple head systems featuring 6 kW lasers had already enabled our systems to reach high processing speeds,” explains Jay Finn, the chief technology officer of LaserCoil Technologies. “But the ability to change between Index Mode and Continuous Mode allows the user to select the mode that offers the best production run from a rate and reliability standpoint. Most parts will run faster in continuous mode, which offers a smooth and steady mode of operation. For production runs that are 10,000 blanks and over, this is the mode of choice for users. In some instances, the length of a single cut path can take longer than the existing cutting window allows at the faster production rate. Rather than split the cuts between the heads, index mode allows the user to choose a mode where the cut can be completed prior to indexing the material.”

https://youtu.be/GZ1otoRMloc

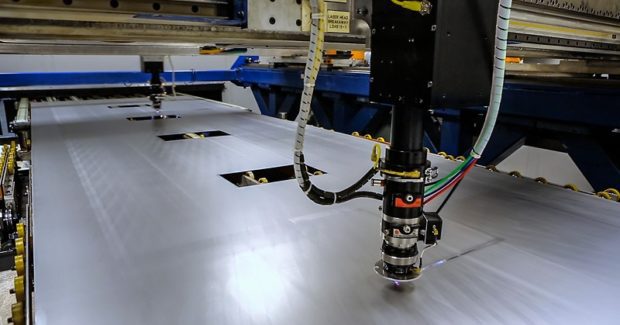

These coil-fed laser cutting systems feature gantry-mounted laser heads stationed in multiple cutting cells that travel along the moving strip and balance the workload. Using linear-induction motors, these laser heads enable cutting of tightly nested, complex curvilinear shapes as the adjustable lanes of the system’s dynamic profile conveyor support the coil strip, automatically repositioning as needed to clear a path for the laser cut. This feature also facilitates gravity-shedding of scrap and offal, delivering completely finished blanks without any scrap to any type of stacking system. From a capital investment standpoint, these systems are flexible and can integrate with any coil line automation, as well as be retrofit into aging blanking press lines. By laser cutting direct from coil stock, these systems provide a fast and flexible approach to blanking that is well-suited for production environments that run multiple blank profiles and mixed material types. The systems can process a wide variety of coil material in aluminum, mild steel, the new high-strength steels, and other materials for surface sensitive panels, as well as structural components in thicknesses from 0.5 to 3.5mm and up to 2.1 m wide coil at any length. To save significant time and money, these coil-fed blanking systems use LaserCoil CAM to automate the importing of part profiles for optimized nesting and laser cutting. LaserCoil CAM accommodates single and multiple cutting heads as well as peripheral automation, such as the dynamic conveyor lanes in the system. In addition to optimizing the part recipes, the software also controls and monitors the system during production.

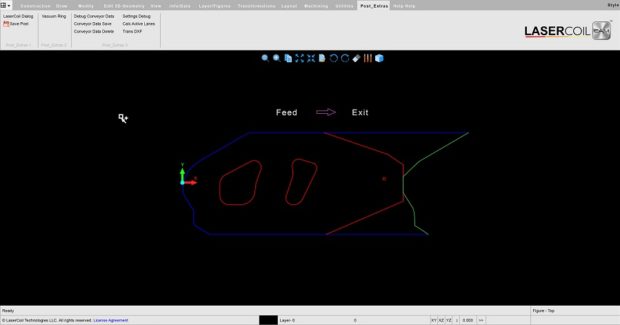

“Creating nesting and cutting programs is a time-intensive process that requires a skilled technician,” notes Finn. “LaserCoil CAM takes only minutes from the importing of CAD files to active cutting of a simple blank. To illustrate its efficiency, imagine if you could design and machine a blanking die for a complex part in less than 30 minutes.” The program is designed for ease-of-use, enabling even less experienced system operators to quickly create an optimized program. The software starts by creating a recipe with pre-built initial cutting parameters that are supplemented with the blank’s profile data imported via a CAD file. The user can either ask the software to select the best coil from multiple coils in inventory, create the best nest for a specific coil width, or permit the program to specify the optimum coil width based upon part yield.

Taking into consideration the appropriate grain constraint for material flow, as well as the part profile, the software identifies the best nesting pattern and then determines how the profiles will be cut by the laser. Next, the operator generates the cutting path and adjustments can be made by simply clicking on the profile parameters and setting a new cutting routine. A simulation is run to show the sequenced travel path of the laser cutting head. The software provides users with a single interface to help reduce programming time and scrap rates, as well as improve their throughput and yield.

LaserCoil Technologies LLC, 476 East Riverview, Napoleon, OH 43545, 419-592-0050, www.lasercoil.com.