Flexible, Expandable CNC for Machining Automotive Parts

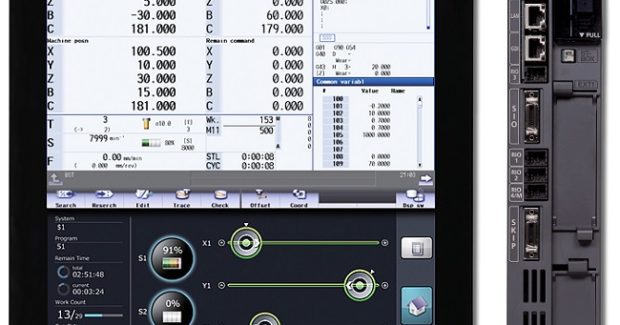

Ideal for turning centers, machining centers, lathes and mills, the M80W CNC from Mitsubishi Electric Automation features a 19 in touch screen display separate from the control unit and a dedicated CPU for improved cycles times, faster program processing, and more accurate machining.

Posted: December 14, 2017

Designed for the automotive and machine tool industries and especially useful for turning centers, machining centers, lathes and mills, the M80W computer numerical controller from Mitsubishi Electric Automation, Inc. (Vernon Hills, IL) features a touch screen Windows®-based display that is separate from the control unit, providing expandability and flexibility. Incorporating the latest operating system and slim personal computer, the M80W includes two expansion slots for 32GB SD cards, allowing OEMs and end users to add up to 64GB more memory for even greater flexibility. The key benefits of the M80W include:

- CNC-dedicated CPU for improved cycles times, faster program processing and more accurate machining.

- Intuitive, touch-screen operation for optimal visibility.

- Improved super smooth surface (SSS) control, reducing machine vibration during high speed cutting.

- High speed, high accuracy mode comes standard, allowing for complex, highly precise 3D mold work.

- User-level data protection allowing for multiple levels of permissions based on operator’s role.

- Field network compatibility with CC-Link®, PROFIBUS® DP, and Ethernet/IP™ for easy connectivity to peripheral equipment and devices.

The M80W CNC includes a 19 in vertical display with a split multiple window that can be customized by arranging a keyboard, operation panel, document viewer or other applications. In addition, real-time servo and spindle tuning helps maintain machine stability by adjusting the control gains automatically.

Mitsubishi Electric Automation, Inc., 500 Corporate Woods Parkway, Vernon Hills, IL 60061, 847-478-2100, us.mitsubishielectric.com.