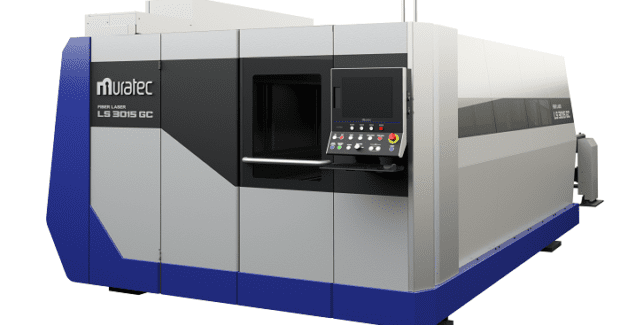

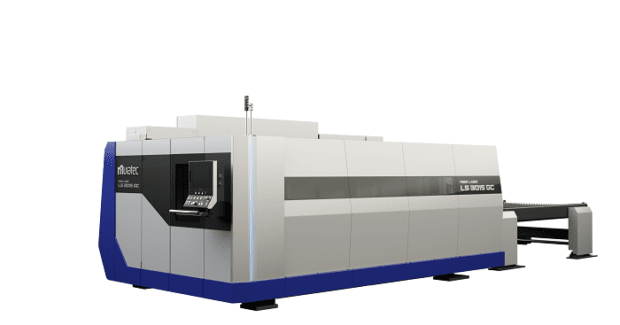

Economical Fiber Laser Cutting of Ferrous and Non-Ferrous Materials

The compact LS3015GC fiber laser cutting system from Murata Machinery uses an integrated flying optics system with internal controls that monitor laser output, laser beam and light reflection for superior cutting of ferrous and non-ferrous materials, including steel, stainless steel, aluminum, brass and bronze.

Posted: December 8, 2017

Murata Machinery USA, Inc. (Charlotte, NC) offers their innovative LS3015GC fiber laser cutting system. With an integrated flying optics system, this machine can cut through both ferrous and non-ferrous materials, including steel, stainless steel, aluminum, brass and bronze. In addition to speed, accuracy, and quality, the LS3015GC also features a smaller footprint and upgraded drive system, and is expected to be an economical laser cutting system. Available in either 2.5 kW, 4.0 kW or 6.0 kW, the efficiently laid out LS3015GC provides performance and reliability at a lower cost. Driven by Fanuc Control and Drives, the rack and pinion system is capable of ±.001 in positioning accuracy and ±.0004 in repeatability. The laser power source from IPG and laser head from Precitec are known and supported worldwide.

Internal controls monitor laser output, laser beam and light reflection to ensure a superior cut. Highly reflective materials can be cut and high quality marking is possible. Automation Ready: By integrating the LS3015GC to Muratec automation, efficient continuous production is possible during the day and after hours. Automation options are available, from simple load/unload to high capacity tower systems. Using data gathered from the machine control, information is available to analyze current and historic machine production.

Murata Machinery USA, Inc., 2120 Queen City Drive, Charlotte, NC 28208, 800-428-8469, www.muratec-usa.com.