Advanced Geometries and Coatings Increase Penetration, Improve Tool Life

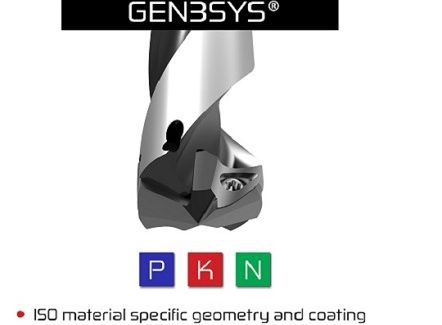

GEN3SYS XT Pro high penetration drilling tools from Allied Machine & Engineering feature inserts and holders designed for three geometries with several different coatings that can be combined and optimized for machining different materials with top results.

Posted: December 19, 2017

Allied Machine & Engineering Corporation (Dover, OH) offers their GEN3SYS® XT Pro line of high penetration drilling tools that feature inserts and holders designed for three geometries with several different coatings. By combining specific geometries and coatings, an optimal system can be created for machining different materials with top results. GEN3SYS XT Pro is available for steels (ISO material class P), cast irons (material class K), and non-ferrous materials (material class N). The drill inserts come in diameters ranging from 11 mm to 35 mmm. Those in steel and cast iron have AM400 coatings, while inserts for non-ferrous materials are coated with titanium nitride (TiN). The steel materials (P) geometry is ideal for increased penetration and excellent chip control in low and medium carbon and alloy steels. The multi-layer AM420 coating increases heat resistance and improves tool life. Tests conducted demonstrate up to 40 percent improvement over competitive drills at the same speeds and feeds.

The K geometry was uniquely designed for cast and nodular iron applications. It includes a corner radius for improved hole finish and heat dispersion. The multi-layer AM440 coating offers increased abrasion resistance and tool life. The N geometry is designed for softer materials and yields excellent chip control in aluminum, brass, and copper applications. The TiN coating provides the versatility to run in a variety of materials while reducing buildup. Holders for the GEN3SYS XT Pro line are offered in numerous depth-to-diameter ratios, including 3xD, 5xD, 7xD, and the 10xD, which features an enhanced flute design that improves chip evacuation and an updated coolant configuration that increases coolant flow and directs coolant to the cutting zone. Available in imperial and metric shanks, these holders come in cylindrical and flanged with a flat.

Allied Machine & Engineering also offers a new catalog that incorporates their comprehensive range of holemaking tools into one feature-packed book. With stunning new images and a design that pays careful attention to helping users select the right tools, this catalog showcases all the drilling, boring, reaming, burnishing and threading tools in one location. Catalog navigation has been carefully thought out to benefit users by saving them time and money. A wealth of technical details about tooling sizes, setup tips, and application guidelines make this catalog a valuable all-around educational resource. Sections are organized in the order in which manufacturing processes would typically be performed: Drilling tools are highlighted first, followed by boring and reaming, burnishing, and then thread milling options.

The final product section details Allied’s vast special tooling capabilities, with case studies showing quantifiable data from users in the field that demonstrates how each tool reduced scrap and/or increased tool life compared to the competition. To further assist with tool selection, products in each section are arranged in ascending order by diameter. Section indicators next to page numbers help users distinguish which section they are viewing. A comprehensive index helps them quickly find items by product number. The catalog also includes a product selection guide to help users quickly decide which tool to use per their specific application. Product imagery has been completely revamped, with new high-resolution images of each tool within a product line. New product renderings and line drawings show extremely clear and accurate product detail.

Also added is a wealth of technical information on each product, including features, advantages and assembly instructions. This section includes helpful explanations of each tool’s performance, application recommendations, set-up and adjustment instructions and tips, available options, and suggestions for which styles should be used in certain situations. Tool recommendation guides provide overviews of each tool line, including material recommendations so that users can quickly and easily find the best system for their applications. While this catalog includes information on the vast majority of Allied’s offerings, a few standalone catalogs remain, including the Wohlhaupter boring system solutions and Eco-Cut lathe tools.

Allied Machine & Engineering Corporation, 120 Deeds Drive, Dover, OH 44622, 330-343-4283, www.alliedmachine.com.