Starrag and Walter Team Up on Turbine Production

They join together to focusing on how digitalization can make turbine manufacturing more productive and reliable.

Posted: November 1, 2017

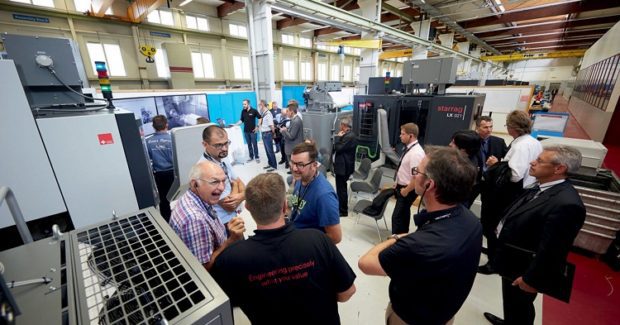

Walter AG (Tübingen, Germany) teamed up with machine builder Starrag AG (Rorschacherberg, Switzerland) to take a step into the future. The venue was the fifth annual “Turbine Technology Days,” held at Starrag headquarters in Rorschacherberg. The event attracted over 200 visitors from 19 countries and focused specifically on ways to make turbine production even more productive and reliable, and, beyond that, on developments in machining and control technology that are changing both turbine production and manufacturing in general.

Turbine production is attracting considerable attention lately, in part because the aviation industry is experiencing a boom, and the power generation sector is also experiencing increasing demand for gas turbines. The consequences: OEMs and suppliers must increase their production while machine builders are being called on to meet higher quality criteria, all while facing increased competition due to globalization. For both companies, the aerospace and energy sectors are strategic business areas in which they are developing application-specific solutions in partnership with their customers.

“Digital solutions are the future of modern machining,” stated Mirko Merlo, the chief executive officer of Walter AG, as he emphasized the importance of digitalization. “It is no longer just about turning, milling, drilling and threading. Perfection and precision are basic requirements. Our company presented solutions that are more than just tools. Tailored and efficient processes are important prerequisites for this.”

For Starrag’s chief executive officer, Walter Börsch, this application-specific approach is the key to making leaps in productivity, which subsequently improve competitiveness. “We have extensive process expertise, which includes machine, tool and device technology, as well as software and control technology,” he said. “This allows us to not only offer machines, but also complete production systems that are precisely tailored to meet the users’ requirements and guarantee maximum benefits.”

Working together, these two companies designed 14 stations that used practical examples to illustrate these opportunities during the event. In addition to machining examples, they also demonstrated the diverse potential improvements that can be gained through digitalization and modern software. The event was joined by nine competence partners whose products – from cooling lubricant, testing and measuring technology and tooling systems, through to software solutions – play a significant role in the process chain.

www.walter-tools.com/us, www.starrag.com/en-us