SPRING Technologies Wins Award

They receive the 2017 MM innovation award for their CNC Simulation Platform that uses a bi-directional 3D database for intelligent and flexible CNC machining.

Posted: October 11, 2017

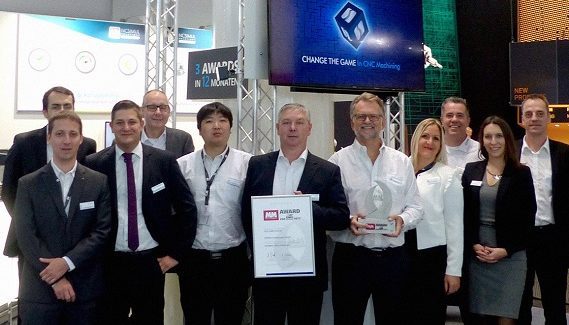

SPRING Technologies (Boston, MA) was awarded the winner by MM Maschinenmarkt in the CAD/CAM Systems category at the EMO Hannover 2017 trade fair for their innovative NCSIMUL SOLUTIONS 2017 CNC Simulation Platform that uses a bi-directional 3D database for an intelligent and flexible CNC machining process. This year’s award ceremony took place on the first day, during which the innovations of all shortlist candidates were honored in various categories, such as automation technology, tools, additive manufacturing, CAD/CAM systems, milling or turning.

The software convinced the jury with its unified, continuous and bi-directional data platform, with faster G-code processing from the engineering department directly to the shop floor with error-free G-code programs. The user has access to all data relating to the CNC machine, tool and technology parameters without any further adjustments, all visualized in 3D. G-code simulation and verification is also integrated in this process, along with tool path optimization, tool management, as well as the automated conversion of the G-code programs.

The automated part transfers to a new CNC machine tool with a different controller and is managed through the software in just a few clicks, whereby the programs are adapted directly to the defined performance of the targeted CNC machine. Digital tool management includes its own integrated 3D module. The master models (respecting DIN4003/ISO 13399 standards) contained in the system are predefined for faster creation of the complete tool set and components.

“The MM Award for EMO 2017 is a great honor and recognition for our development on the intelligent and flexible CNC production of the future,” said Herbert Schönle, the general manager DACH of SPRING Technologies. “This is the our fourth innovation prize in 18 months,” added Gilles Battier, the company’s chief executive officer. “It confirms our market vision of developing a software solution that is accessible, with a fast learning curve and easy implementation to meet the real requirements of CNC manufacturing, covering Industry 4.0 challenges. Thanks to our digital evolutions, we are on the right track.”