Run Out on a Rail

The chip conveyors in this shop that manufactures railroad car components were falling apart due to jams they couldn’t handle from the bushy stringers of steel chips coming off two turning centers. What could they do? They found the answer in a unique dual-belt stacked conveyor arrangement that reduces or even eliminates jamming problems.

Posted: October 9, 2017

Amsted Rail Brenco Bearings (Petersburg, VA) is a leading manufacturer of railroad car components and systems that realized their existing chip conveyors were falling apart. The conveyors were handling chips from the turning of large steel parts on Murata MW400 and MW200 twin spindle CNC chuckers and were constantly jamming up from having bushy stringers not being conveyed out of the current units. From what machining process engineer Mark Vieira observed, the maintenance technicians were using a pipe wrench on the motor shaft to force the conveyor past the jam. These old conveyors were also attached to each machine above the coolant tank, which allowed a lot of chips and debris to fall into the tank. “We normally run 24/7 operations, so the coolant tank would fill with chips and have to be cleaned every three months,” said Vieira.

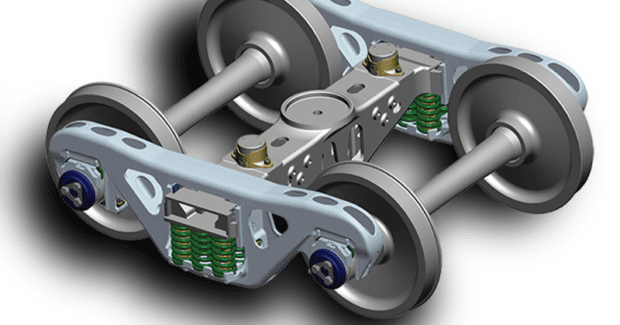

He attended an IMTS show in Chicago and visited the booth of Jorgensen Conveyors, Inc. (Mequon, WI), where he learned about their Munchman® II twin-belt chip conveyor. They showed him the workings of the conveyor system and how it would help with the issues his shop was having with the bushy stringers. The Munchman II employs a unique dual-belt stacked conveyor arrangement at the lower curve and through the incline and chip discharge of the system that reduces or even eliminates material conveyance and conveyor jamming problems. None of the parts are welded. Instead, each part, made of extra heavy gauge steel, is held by an axle that passes through the part. If a part should become damaged, the belt assembly is completely detachable so that the part can be replaced quickly. This system also features fewer parts, making it more cost effective.

In the Munchman II a single drive runs both belts for efficient operation. This system is ideal for turning and milling operations where long stringy and heavy chip volumes are generated. Vieira contacted a sales representative and started the process of putting this chip conveyor into all of their Murata twin spindle turning centers. “We design custom systems to meet the needs of users,” noted John D’Amico, a co-principal of Jorgensen. “With any new order, our engineers create and model designs using SolidWorks to solve a specific application need. The selected design then moves into our 100,000 sq ft state-of-the-art manufacturing facility that maintains ISO 9001 certification.” For Amsted Rail Brenco, they designed a coolant tank and chip conveyors for the Murata MW400 and MW200 twin spindle turning centers with the chip conveyor sitting down into the coolant tank to allow better chip carry out. The chip conveyors were also equipped with a Jam Manager® control that automatically clears chip conveyor jams and returns the conveyor to normal operation quickly and smoothly.

The primary components used by the control for automatic clearing are a power inverter and a programmable logic controller (PLC). When a jam occurs (i.e., when the drive motor current exceeds the specified threshold) the PLC stops the conveyor, pauses, and reverses the direction of belt or drag chain travel. After operating in reverse for a prescribed length of time, the conveyor again stops, pauses, and again operates in the forward direction. This is called the “clear cycle.” When a jam occurs, the length of time that the conveyor pauses before reversing direction is called the “forward time delay” or “reverse time delay.” If the jam has still not cleared, the clear cycle will be repeated until the jam clears or until the prescribed number of clear cycles has been satisfied (the factory default setting is five cycles, but Amsted Rail Brenco changed this setting to three cycles).

Typically, the time of each successive reverse cycle is longer to clear the more difficult jams. When a jam is cleared, the value in the jam cycle counter does not immediately reset to zero. Reset occurs after the conveyor operates for a prescribed time without incurring an additional jam (auto reset time). If the jam is not cleared after the specified number of cycles (known as “clear fail”), the control will shut down the conveyor and alert the user. “If something falls into the conveyor or if the quantity of bushy chips that are in the conveyor jams the conveyor, the control automatically backs up the conveyor and goes forward again three times to try and clear the jam before stopping. We then clear the jam manually. This saves our conveyors from being damaged because of attempting to force the conveyor to pass the jam through.”

Before this new system was installed, the shop would lose 96 hours of production per machine each year to clean our coolant tanks during regular working hours. “We reduced our coolant tank cleaning from once every three months to once a year,” recalled Vieira. “We are now able to clean our coolant tanks during our normal shutdown weeks so that we do not lose any production time for coolant tank cleaning. Only having to clean the tanks once a year means we have also reduced our coolant tank hazardous waste removal by 75 percent. This, along with regular maintenance, should afford us a much longer chip conveyor life. Our old chip conveyors lasted three years. Our new conveyors have been in place for three years and are still performing very well.”

Amsted Rail Brenco Bearings, 2580 Frontage Road, Petersburg, VA 23805, 804-732-0202, www.amstedrail.com.

Jorgensen Conveyors, Inc., 10303 North Baehr Road, Mequon, WI 53092, 262-242-3089, Fax: 262-242-4382, www.jorgensenconveyors.com.