From Napkin Drawing to Mass Production

This medical parts supplier specializes in alternative design solutions and value-added engineering that reduces manufacturing costs, risk and time to market. When they took on the steep challenge of manufacturing a non-conventional, unusually complex part, they needed a machine tool supplier with the same expertise, one that could identify the ideal system for the job and provide technical support to get production running smoothly in no time.

Posted: October 5, 2017

The demand for high quality, short lead times and competitively-priced manufactured parts has never been higher. Successful shops increasingly look towards optimizing their machine tools for the application at hand to ensure the most effective, efficient production processes. But not all machines are equal; what works for a high mix/low volume operation may not be the best fit for a complex, high volume application. This is the situation that Precision Swiss Products, Inc. (PSP; Milpitas, CA) faced when they decided to take on an attractive, but dedicated, high volume job with a steep challenge of manufacturing a non-conventional part.

PSP is an innovative turnkey manufacturing partner that facilitates the “napkin drawing to mass production” product lifecycle, specializing in producing extremely complex, tight tolerance components for the medical and aerospace industry that routinely require micron accuracy levels. Positioned as a total cost supplier, they maintain a partnership with a team of Design for Manufacturability (DFM) experts that can help meet customers’ financial strategic goals of lowering costs and/or lead times without compromising quality. “We want to work closely with our customers to reduce total product life cycle costs,” explained Norbert Kozar, the chief executive officer of PSP. “This includes understanding what drives ongoing maintenances costs, part rejection costs across all vendors, and unnecessary part requirements that contributes to the manufacturing costs.”

Founded in 1974, PSP was acquired by Kozar in 2007 with sales at $2 million, a very diverse customer base, and lots of potential to grow sales: all they needed was a marketing plan, a salesman who could capitalize on the existing customer base, and new relationships built through a new quality-driven strategy method. By 2013, sales had mushroomed to $6 million, rising to $7.5 million a year later and over $10 million in 2015 – growth of 38 percent that was fueled by their expertise in alternative design solutions and value-added engineering that helps reduce manufacturing costs, as well as risk and time to market. PSP runs two full shifts and a weekend shift with 65 employees in a 22,000 sq ft manufacturing facility in Silicon Valley that has two wire EDMs, three horizontal machining centers, six vertical machining centers, four lathes, six FANUC Robodrills, 14 Swiss precision screw machines, as well as passivation equipment and a Nakamura AS-200 multi-tasking turning center.

They earned their ISO 13485 and AS9100 certifications within four to five months in 2007 – a very rare circumstance – and their goals moving forward are to expand capacity and continue tackling higher tolerance work. “Interestingly, we are moving away from low volume/high mix applications to high volume, dedicated solutions,” noted Steve Dillon, their chief operating officer/chief financial officer. “For example, we took on a job manufacturing a component of a heart valve delivery system, where a stent is delivered to expand blood vessels to the heart and implant the heart valve. This part is approximately 1 in diameter and 2 in long and we are manufacturing about 1,250 parts per week in the polycarbonate resin Lexan.”

A HEART-TO-HEART WITH THEIR MACHINE TOOL SUPPLIER

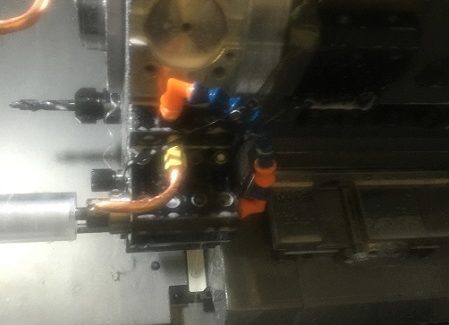

“We challenged Methods Machine Tools, Inc. (Sudbury, MA) to recommend a machine that could handle this part in a turnkey, high production run,” recalled Dillon. Methods stepped up to the challenge at their state-of-the-art 10,280 sq ft Northern California technology center in San Leandro, where all of their equipment is showcased and training, application support, engineering and customer service are offered. “They proposed the Nakamura AS-200 high performance multitasking turning center and a unique custom programmed chip management system for the job,” continued Dillon. “We were a bit skeptical that finding the right system was going to be an easy process because this is a very unusual, difficult part to machine. You have to be very careful not to let the friction and heat melt the part because we’re working with Lexan. We sent them some solid models and a part diagram. They programmed the part, made refinements and within one month we were ready to move ahead on producing it – we were incredibly impressed with that level of engineering expertise and service.”

The AS-200 features a single 4,500 rpm spindle and a 7.5 hp milling motor on a 6,000 rpm 12-station turret featuring 24-tool capacity in a heavy duty, compact machine. The machine is equipped with a high speed C-axis and 82 mm stroke Y-axis for accurate, finished parts. Maximum turning diameter is 13.4 in (340 mm) and maximum turning length is 11.8 in (300 mm). The turning tool is 1.0 in (25 mm) and the inside boring shank is 1.25 in (32 mm). The AS-200 has a 10.4 in high-resolution LCD panel that works in conjunction with the latest Fanuc 0iTD controller to give a high degree of functionality, coupled with fast processing speeds. Its NT Nurse II software provides user-friendly operation, programming and production support. In addition, NT Work Navigator software facilitates easy part set-ups with no fixtures required.

“This part is fairly complex and requires both inner and outer diameter Acme threads that produce many nuisance chips,” added Kozar. Initially, the AS-200 produced foot-long chips that were slowing down the production process. To address this problem, Methods created a chip management system using a single point 60 percent carbide bar for pecking, along with programming solutions that cut the chips down to a much more manageable size of four inches or five inches. “The frequent pecking action, along with the friction and heat generated by the production process, creates substantial wear on the tools,” stated Kozar. “We now currently run diamond coated drills in an effort to further extend tool life and reduce downtime related to changing worn out tools.”

ROI IN NO TIME

The Nakamura AS-200 was just what the doctor ordered for this complex part. “We were very impressed with this turnkey system,” said Dillon. The AS-200 runs mostly lights out, approximately 20 hours a day, consistently providing high tolerance, exceptional quality parts. While performance is a key component of success, PSP also needed to justify their investment in the equipment. “Payback was incredibly fast,” added Dillon. “We broke even on the machine within six and a half months. Most of the time, machine installations and qualifications encounter some hick-ups. Methods made these problems insignificant by providing sales and engineering support, even on the weekend. Armand Flemate, their sales representative, orchestrated a high pressure coolant pump exchange on a Saturday afternoon and by Monday afternoon, we had a higher pressure coolant pump that resulted in an improved chip control system. This type of service and commitment is hard to find and is the most overlooked attribute of a new machine acquisition.”

While manufacturing complex parts can present a number of challenges, working with a machine tool supplier who can help identify the ideal system for the job and provide reliable technical support throughout the process can streamline the process and have production running smoothly in no time.

Precision Swiss Products, Inc., 1911 Tarob Court, Milpitas, CA 95035, 408-433-5880, Fax: 408-434-0764, [email protected], www.precisionswiss.com.

Methods Machine Tools, Inc., 65 Union Avenue, Sudbury, MA 01776, 978-443-5388, Fax: 978-440-9405, www.methodsmachine.com.