Tooling and Industry 4.0: How We Got Here and Where We’re Going

How in the world could all of this connectivity, this digital thread, extend to the very smallest of metalworking equipment and tooling in a way that could possibly have a dramatic effect on shops? It’s already happening and will continue to have increasing impact, because we’re only one hurdle away from a world of endless opportunities.

Posted: September 6, 2017

When manufacturing pros consider Industry 4.0, it most often sparks thoughts of high level production data, inventory management, or integrated and responsive workflows – but you may wonder: How in the world could this connectivity, this digital thread, extend to the very smallest of metalworking equipment and tooling in a way that could possibly have a dramatic effect on shops? The short answer is that it’s already happening and will only continue to have more and more of an impact. Let’s take a look at how we got to where we are today and where we’re going.

THE TOOL

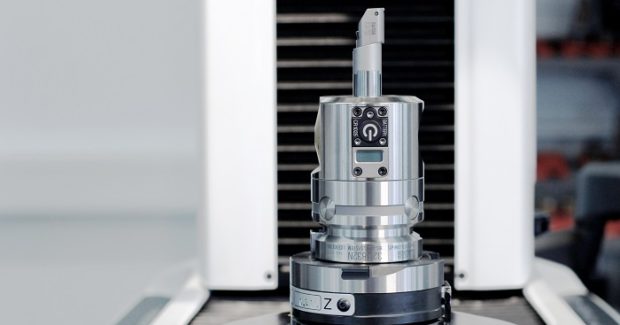

The move to connectivity started years ago here at our company. The first logical step was digital readout boring heads. Needless to say, a rugged machining environment and digital components aren’t always a natural pair, so we employed a highly advanced technology that remains very high functioning in exceptionally small forms to combat the ambient factors: anisotropic magnetoresistance (AMR), or solid-state magnetic sensors. In other words, when a tool is adjusted, changes in magnetic forces are recognized and translated to the digital readout with extreme precision and consistency in increments of 0.00005 in. When compared to electro-optical digital technology, or glass scales, there are far fewer moving parts, making it much easier to secure and protect against dust or coolant.

Our EWE digital boring heads, for example, are rated to IP69K, the highest ingress protection rating available for electronic equipment. Digital heads stand on their own as a major leg up for shops that employ them: they help prevent operator error in on-the-fly adjustments and rounding, they’re operated completely with a single button, and the guesswork in insert-wear tracking is eliminated. After that, the next step toward Industry 4.0 compatibility was tying the digital thread between digitally capably in-machine tools and external devices.

THE CONNECTION

Nowadays, everyone probably has experience with wireless communication. But what you may not realize is that there is a wide variety of types of wireless communication, with differing speeds, ranges and bandwidths. Since the ranges are short and the volume of data being transmitted in these tooling setups are relatively small and intermittent at this stage, we’re able to capitalize on a very specific type of connection that uses low energy and tiny hardware. As a result, we can integrate the instruments right alongside the digital readout equipment without sacrificing the seal or creating an imbalance. What’s more, the batteries that power the connection can have a lifespan of years, extending maintenance intervals.

THE REMOTE DEVICES

The digital and connectivity stages were developed in parallel and have come together in the last year with the release of our boring app, driving full steam ahead toward Industry 4.0-level integration. The boring app, now available for free download on both iOS and Android devices, unleashes long-planned capabilities. In addition to having operating manuals for dozens of our boring heads at your fingertips and easier in-machine adjustments, critical measurements and setups of compatible digital heads can be stored and tracked. Machine and tool data, parameters and settings are readily available for real-time calculations and adjustments in metric or imperial units. Having this type of precise information available on-demand in the palm of your hand enables smarter, faster decision making.

One such example is the ability to program a bore size: After making a measurement of a bore diameter with a bore gauge, the desired bore diameter can be programed into the app, with tolerances, so that the operator knows how to adjust the boring head. With the help of a colored readout, it’s clear how in or out of tolerance the head is.

WHERE WE’RE GOING

While the capabilities we’ve been discussing here are game-changing in and of themselves, they are only the tip of the iceberg. Imagine the possibilities. In terms of connectivity, the tool-presetter-machine triad has the potential to change manufacturing forever . . . my colleague Doug Sumner wrote about the presetter piece of this equation in Make the Most of a Tool’s Entire ‘Life’ in the January 2017 issue of Fabricating & Metalworking. As I write this, we’re investigating how to integrate more sensors into heads for the relay of even more information: things like machining time, vibration levels, balance, tool clamp/release and sending automatic tooling adjustments from the bore gauge to the head. And we’re not stopping at boring heads.

The industry as a whole needs to overcome one major hurdle: a standard for inter-machine and intra-machine communication. Once that is established, the opportunities are endless. In the meantime, rest assured that we’ll be pushing the limits of what’s possible in the area of tooling, stretching the digital thread all the way to the cutting edge.