The King of Cutting Sheet Metal Up to One Inch Thick

When jobs call for cutting sheet metal in thicknesses around one inch and under, waterjet and plasma cutting pale in comparison to laser cutting. Here are the reasons why it is the clear front runner for shops that compete in this type of work.

Posted: September 6, 2017

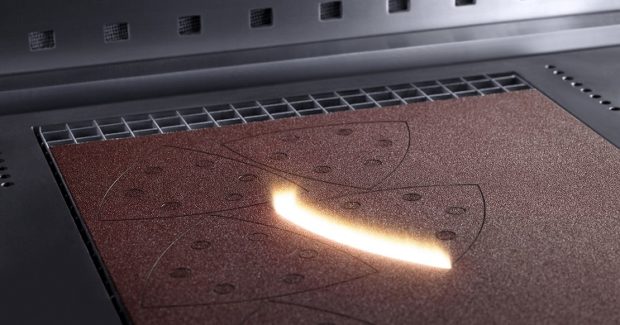

The cutting of materials is one of the most common processes performed in sheet metal fabrication. Shops must choose whether a laser cutting machine, a plasma cutting system or an abrasive waterjet will work best for their operation when cutting sheet materials. Many variables must be taken into account when comparing these three popular options: the type and thickness of the material to be processed is a primary consideration, as well as the specific geometry of the cut part, along with its quality and accuracy specifications. Waterjets tend to be slower in terms of cutting speed and they can be costly to operate, but they can also cut very diverse material types, including metals, plastics, composites and even organics. Lasers and plasma cutting systems deliver better productivity and lower operational costs, but both are generally limited to cutting metals.

However, when jobs call for cutting sheet metal in thicknesses around one inch and under, waterjet and plasma cutting pale in comparison to laser cutting, the clear front runner with many advantages that are mostly due to its relatively low operational costs, speed of processing, and quality and accuracy of its cut parts. Shops that use lasers to cut sheet metal up to one inch thick can expect:

- Lower operating costs. The best fiber laser cutting machines will cost around $3 an hour to operate. In contrast, a typical plasma cutting system can be six or seven times that, costing upwards of $20 an hour or more to operate. Waterjets tend to be, by far, the most costly option per hour of processing time and will also have the longest cycle times per part in sheet metal materials. The difference in operating costs can be attributed to a few major factors, such as wall plug efficiency, cost of consumables required for cutting, and maintenance requirements of the equipment.

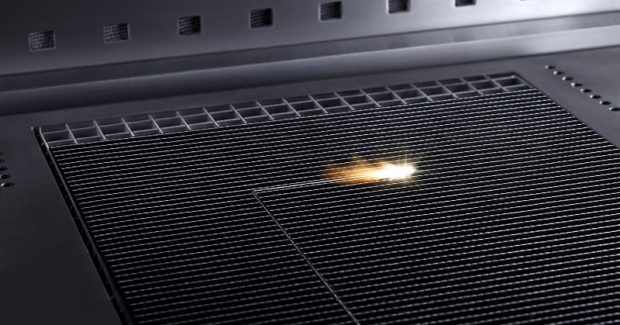

- Faster cutting speeds. In addition to lower operating costs, laser cutting machines also boast faster cutting speeds than both plasma systems and waterjets. For example, a typical waterjet can process ¼ in mild steel at approximately 45 ipm. A typical plasma cutting system will process it at about 70 ipm. A laser cutting machine can process the same ¼ in mild steel at 114 ipm or more (depending on the laser source). The laser cutter will always have a higher throughput when processing sheet metal.

- Better part quality. Along with fast cutting speeds, the part quality is excellent when cutting sheet metal on a laser. Waterjet and plasma cutting both tend to produce a rougher edge condition with lower geometric tolerances than laser cutting. As laser technology advances and the beam size can be optimized for cutting even thicker material, the traditional advantages for high definition plasma and waterjet cutting (of thick materials) have been eroded.

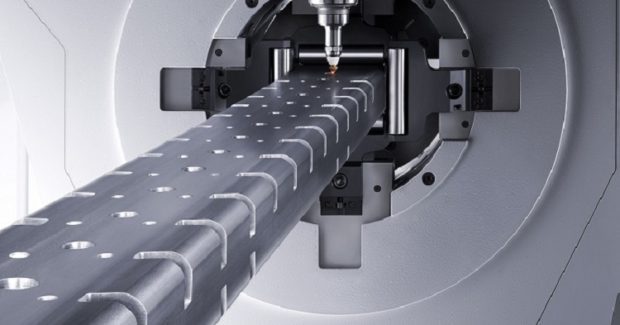

- Versatility. A laser cutting machine can perform a variety of functions, including cutting, ablation, drilling and engraving, to name a few. In contrast, the plasma cutting system can only cut, and the waterjet is limited to cutting, ablating, and structuring.

- Maintenance. Both plasma cutting systems and waterjets require day-to-day maintenance, with waterjets being especially sensitive to maintenance requirements due to the water and abrasive medium. By comparison, laser cutting machines have few consumables and require minimal maintenance. With solid-state laser sources, the beam delivery system is maintenance free. Also, the laser cutting machine requires very little clean up, but clean up for a waterjet machine is both critical and labor intensive.

- Safety. While the waterjet generates significant noise and pollutants and requires safety gear, the laser cutting machine is very quiet and needs minimal to no safety gear to operate. Laser machines are generally fully enclosed to protect personnel in the area of the machine while it is in operation, and normally include dust collection and filtration systems to eliminate dust and smoke generated from the laser cutting process. Plasma cutting systems also require safety glasses and create noise, although not as much as the waterjet. They also tend to produce copious amounts of smoke and dust in the environment while operating.

Taking all of these factors into consideration, laser cutting is the obvious choice when cutting sheet materials up to one inch thick: cutting speeds are faster, maintenance is less, safety equipment is often unnecessary, cut part quality and accuracy is superior, with higher productivity and lower operating costs. If your shop needs to compete in this type of work . . . when choosing a cutting machine, look no further than a laser.