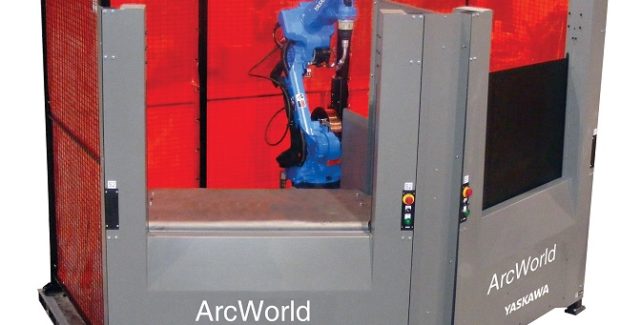

Robotic Workcells for Low to Medium Runs of Small, Medium and Large Parts

The modular ArcWorld 2000 workcell from Yaskawa America is specifically designed for the robotic welding of large parts, while the ArcWorld 200 and ArcWorld 500 welding systems are versatile workhorses for small- to medium-sized parts or medium-volume production runs.

Posted: September 22, 2017

In Booth B17020, the Motoman® Robotics Division of Yaskawa America, Inc. (Dayton, OH) will feature their new ArcWorld® 2000 welding workcell, a modular system specifically designed for robotic welding of large workpieces. This powerful, flexible, pre-engineered system is perfect for low- to medium-volume manufacturers with a medium to high mix of parts. Able to handle parts up to 5 m wide and payloads up to 6,300 kg, the ArcWorld 2000 is ideal for labor intensive jobs involving large parts or heavy deposition welding. This workcell is configured with one or two six-axis Yaskawa welding robots directed by a DX200 controller with menu-driven arc welding application software, an integrated welding package (power source, wire feeder and welding torch), positioner(s), operator interface and safety barriers.

The ArcWorld 2000 scales easily from a single-station layout with a reduced floorspace footprint to a two-robot dual-station configuration that makes it easily adaptable to changing production demands. Two-station layouts can be configured with a “blank station” that allows end user-supplied equipment to be installed, and each station can have a different positioner. In dual-robot installations, the second robot controller can be a reduced cost, dual-robot control type module (DRC). Multiple positioner and robot options combine to deliver a modular system for manufacturers of heavy transportation, agriculture and construction equipment. For maximum welding reach, the ArcWorld 2000 can be configured with two Motoman MA3120 robots. Additional welding robot options include the MA1440 and MA2010 models.

The ArcWorld 2000 takes advantage of the DX200 controller’s Functional Safety Unit (FSU) features as part of the total safety environment, which allows continuous station welding during part loading/unloading. Access to positions at either station is protected by light curtains. Peripherals, such as torch cleaners or tip-changing stations, are installed in a fenced center zone to allow operator access to stations while robot maintenance functions are performed. Cable management is accomplished via a fence mounted wire way that provides protection while safely keeping cables off of the floor, eliminating trip hazards. A MotoMount™ fixture mounting system can be included to eliminate the need for laser or transit alignment procedures, allowing for fast positioner setup and improved equipment life.

Also on display will be their ArcWorld 200 and ArcWorld 500 welding systems that are designed to be versatile workhorses for small- to medium-sized parts or medium-volume production runs. These customizable models feature a dual-station design allowing for high robot utilization: the operator can load one workstation while the robot is servicing the other. Floorspace requirements are minimal, as they can occupy a typical single-station space. The AW200 and AW500 cell designs allow tooling to be quickly changed. Each workstation can be tooled for different parts or can be used for sequential operations. Both workstations feature a simple, rugged, electrically driven barrier door with a two-second cycle time. The Functional Safety Unit (FSU) provides an additional layer of safeguarding between the two stations without switches or a safety PLC, reducing cost and complexity.

The AW200 and AW500 can be configured with either a high speed six-axis MA1440 or a seven-axis VA1400 II arc welding robot that services both stations. A variety of weld packages are available. The ArcWorld 200 is designed for workstations with stationary tooling or a tack table. Risers are provided to allow end users to place their own tooling in the workstation, and each station accommodates a work area of 600 mm x 1,300 mm. ArcWorld 500 workstations include an MHT185 positioner equipped with a MotoMount tool mounting system that eliminates the need for precise alignment of the headstock and tailstock. Coordinated motion is standard between the robot and each positioner. Dowel pins can be used in MotoMount to allow rapid and accurate changeover between multiple parts/fixtures. Each station can accommodate a maximum part size of 1,000 mm x 800 mm. Both models feature a total safety environment that complies with ANSI/RIA R15.06-2012 and relevant ISO and CSA safety standards. All ArcWorld solutions arrive pre-assembled for quick setup and deployment.

Yaskawa America, Inc., Motoman Robotics Division, 100 Automation Way, Miamisburg, OH 45342, 937-847-6200, Fax: 937-847-6277, www.motoman.com.