Modular Fixturing Systems for Welding Reduces Downstream Installation Times

A pneumatically-controlled braking option for manual rollover positioners from Bluco can be retrofitted to existing units to provide constant friction that prevents rotation unless the foot pedal is engaged to allow rotation of the center axis.

Posted: September 19, 2017

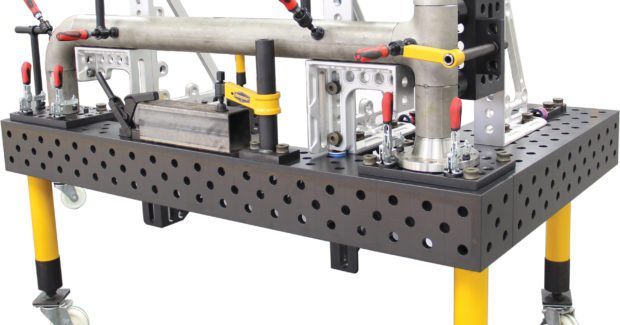

In Booth B19025, Bluco Corporation (Aurora, IL), an industry leader in modular fixturing systems, will introduce new capabilities to their pipe welding and rollover product lines. For pipe welding, they have added an ANSI 1,500 lb Flange Adapter Plate model. These 1,500 lb adapter plates join the existing line of 150 lb, 300 lb, 600 lb and 900 lb ANSI plates that are used in the setup of precision fixturing for piping weldments. Each adapter plate includes a set of mounting pins that can be positioned to match the bolt circle of ANSI standard flange diameters. The mounting pins help the welder to easily mount and align the flange in the fixture, which results in more consistent weldments. Downstream installation times are greatly reduced when the piping assemblies are welded correctly the first time.

The standard 1,500 lb flange plate is compatible with flange diameters ranging from ½ in to 2 in, and custom sizes are possible. All Flange Adapter Plates are compatible with Bluco’s industry-leading modular fixturing system that includes angles, risers, spacers and clamps for further adjustability and positioning of the flanges and entire piping assembly. When combined with their extensive catalog of Modular Fixturing components, shops can setup and weld pipe spools of unlimited sizes and shapes. In addition to the new 1,500 lb adapter plate size, all of their Flange Adapter Plates are now available in hard-anodized aluminum that greatly reduces weight and handling requirements.

Also being showcased is a pneumatic braking option for their line of manual rollover positioners. This braking option can be retrofitted to existing units to allow users to add an additional level of safety to operations that involve the rotation of parts. The pneumatically-controlled brake provides constant friction to prevent rotation unless the foot pedal is engaged to allow rotation of the center axis. The operator can rotate the workpiece to the desired location and then work safely, knowing the air brake is engaged to prevent the workpiece from moving unexpectedly. The rollover positioners are also offered with a hydraulic lift configuration to allow for wide parts to be raised to a height that allows for 360 deg rotation and then lowered back to an ergonomic working height. If the workpiece needs to be rotated in an out-of-balance position, the headstock bearing can be configured with gear reducer assemblies to make it easier and safer for operators to manipulate the workpiece to the desired position.

Bluco Corporation, 3500 Thayer Court, Aurora, IL 60504-3108, 630-637-1820, www.bluco.com.