Innovative, Ultra-Fast Tube Cutting Software

Fully integrated inside SOLIDWORKS and capable of programming all tube shapes and sizes, SigmaTUBE X1 automated tube cutting CAD/CAM software from SigmaTEK is a complete tube cutting system for 4-axis, 5-axis and 6-axis cutting machines that automatically processes and programs entire assemblies.

Posted: September 15, 2017

In Booth A4442, SigmaTEK Systems, LLC (Cincinnati, OH) will feature the latest version of their automated tube cutting CAD/CAM software, SigmaTUBE X1, which offers new features and significant improvements which are a result of their on-going commitment to delivering elegant, effective software through continuous innovation. SigmaTUBE helps tube fabricators complete mission-critical work. It is a complete tube cutting system for 4-axis, 5-axis and 6-axis cutting machines that automatically processes and programs entire assemblies. The software is fully integrated inside SOLIDWORKS and is capable of programming all tube shapes and sizes. This fastest full assembly processing tube software on the market now has even more added features with the release of SigmaTUBE X1.

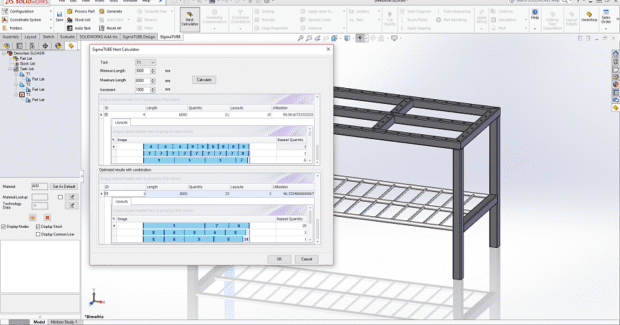

The new Best Stick Nesting feature is a 1D nesting option that gives shops the best overall yield possible based on their stock selection. Users can either select Best Stick Fixed to use a single length stock or they can choose Best Stick Mixed to allow mixing and matching. SigmaTUBE X1 has also expanded the functionality of the new Best Stick Nesting feature into the Nest Calculator tool. The new SigmaTUBE Nest Calculator is a material optimization tool that calculates the ideal stock length for a task. Using the minimum and maximum length and allowed increment, the calculator displays a complete stock comparison, which shows you the lengths that yield the highest utilization percentage. This is also a tool that fabricators can use for quoting to determine how much stock they need to complete a job prior to programming.

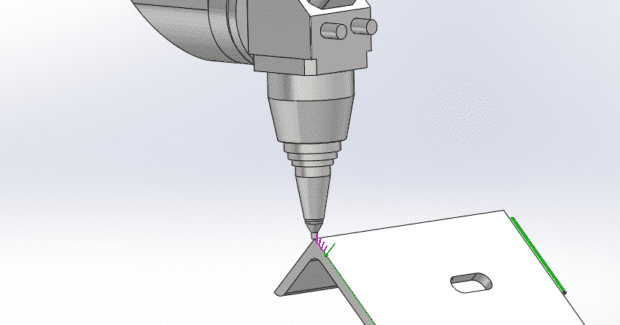

SigmaTUBE X1 also offers a Single Pierce Open Section Toolpath option for channel and angle profiles that interpolates cuts on sharp corners, allowing a single toolpath to be used for the end cuts. Basically, this option provides a single cut rather than multiple passes, decreasing cut times. “Our SigmaTUBE users drive the direction of our product and we are committed to providing them with the best possible solution for their needs,” says Dakota Baird, the SigmaTUBE Product Manager, as he describes the new features and improvements in SigmaTUBE X1.

SigmaTEK Systems, LLC, 1445 Kemper Meadow Drive, Cincinnati, OH 45240, 513-674-0005, www.sigmanest.com.