How to Machine Bulky Parts

The flexible MULTImaster system from Suhner is ideal for machining profiles that are too large or difficult to handle using normal workholding or machining methods.

Posted: September 15, 2017

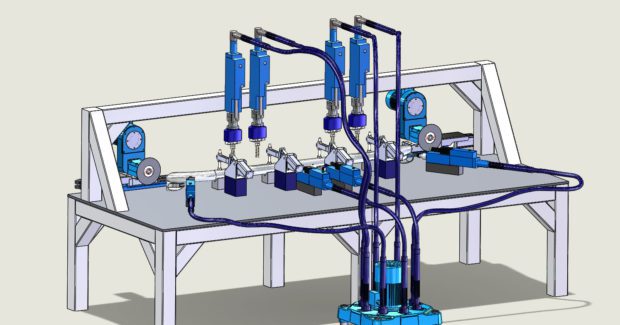

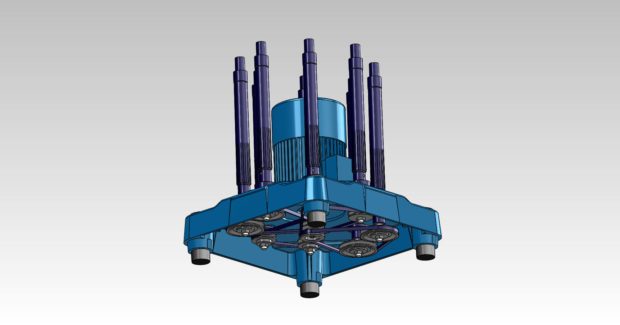

In Booth B35022, Suhner Industrial Products Corporation (Rome, GA) will feature their unique MULTImaster system for machining bulky parts that are too large or difficult to handle using normal workholding or machining methods. For example, to machine an aluminum profile that is 6 ft long requires a CNC mill with a large enough bed to handle the part length (see Figure 1A, 1B). What to do? With standard components, the MULTImaster system can drive up to eight drilling spindles with a single electric motor via flexible shafts (see Figures 2A, 2B). This system is made up of three main components: a drilling spindle that is available in three sizes of quill feed units and three sizes of basic drilling spindles, a flexible shaft (cable which transfers rotary motion) that is available in three standard lengths and sizes, and a base unit (electric motor with flex shaft connections) that is available in different motor sizes.

Instead of directly driving a spindle with a motor, the base unit uses a 3 kW motor and belt and pulley combination to drive the drilling spindles through flexible shafts. The flexible shaft can then be connected to a variety of drilling spindles in a setup that offers several advantages:

- Efficiency: one motor and controls rather than multiple.

- Versatile mounting: mount units in any direction.

- Remote operation: move motor away from coolant.

- Weight: units are lighter without motor directly coupled.

- Close mounting: allows for close hole distances

The greatest advantage to using the MULTImaster system is flexibility. With the available options of varying speed, flexible shaft length, motor size and a wide variety of spindle types, there is no part that is too bulky for this spindle system.

Suhner Industrial Products Corporation, Highway 411 S Suhner Drive, PO Box 1234, Rome, GA 30162-1234, 706-235-8046, Fax: 706-235-8045, [email protected], www.suhner.com.