Groove Turning Goes Deep

The GROOVEX VG-Cut system from Vargus now includes double-sided blades with high pressure coolant for deep grooving and parting off, and a Modular system with high pressure coolant for deep grooving, parting off, turning, profiling and face grooving.

Posted: September 18, 2017

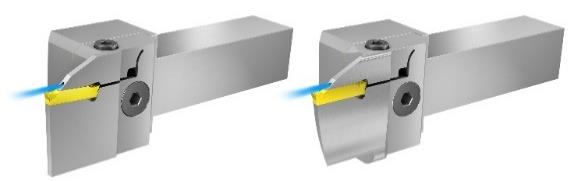

The rapidly growing GROOVEX VG-Cut system from Vargus USA (Janesville, WI) provides a complete range of turning systems, including double-sided blades with high pressure coolant for deep grooving and parting off that feature:

- High pressure coolant.

- Better chip formation and evacuation.

- Longer tool life.

- Blades are available for 3 mm and 4 mm insert pocket width (PW).

- Suitable with standard VG-Cut blade holders 26 mm and 32 mm Blade height (B).

The GROOVEX VG-Cut system also includes a new Modular system with high pressure coolant for deep grooving, parting off, turning, profiling and face grooving that features:

- High pressure coolant.

- Better chip formation and evacuation.

- Longer tool life.

- Horizontal and perpendicular bodies in 20 mm, 25 mm and 32 mm height (H/H1).

- Complete offering of radial modules with high pressure coolant for 2 mm to 6 mm inserts for deep grooving, parting off, turning and profiling applications.

- Comprehensive range of face grooving modules with high pressure coolant for 3 mm to 6 mm inserts for face grooving and turning applications.

Additionally, there are now 22 tools available from stock of reinforced monoblock tools (PH family) for parting off, deep grooving and threading applications in 2 mm and 3 mm insert pocket widths. VG-Cut also offers internal grooving and turning systems with internal boring toolholders with high pressure coolant for 2 mm to 6 mm insert pocket width. Vargus has also continued to develop their offering of VG-Cut insert grades – VPG, VMG, and VKG – with many more inserts now available as standard stock items.

Vargus also offers their rapidly growing GROOVEX GrooVical program for precise grooving and turning applications that has introduced a new close-to-shoulder super positive rake grooving insert that features:

- Up to 30 deg extra positive rake angle.

- Lower cutting forces.

- Suitable for low-strength ferrous and non-ferrous metals.

- Ideal for small part machining in shallow grooves.

- Improved chip formation.

- Designed to prevent crater wear and chip build-up.

This new super positive rake grooving insert is available in GVN26 and GVN29 geometry with tmax up to 4.90 mm. The insert is offered in the popular multipurpose VTX grade, as well as the VKX grade upon request.

Vargus also introduces important additions to their GROOVEX micrOscope system for internal micro machining operations in bores as small as 1.0 mm, including three new toolholder designs for increased clamping and versatility that feature:

- Economical shrink toolholders with a newly designed grip for vibration reduction and longer tool life, with shrink tools that are available for all micrOscope inserts in 4 mm to 7 mm insert diameter.

- Round tools and double-sided round tools without shoulder in a four-flat design that can be placed from both sides of the machine tools table. These round tools are available for all micrOscope inserts in 4 mm to 7 mm insert diameter, and double-sided round tools are available in 4 mm and 5 mm or 6 mm and 7 mm.

Another important addition to the GROOVEX micrOscope system are select micrOscope inserts with coolant in different boring and grooving operations that feature:

- High pressure coolant thru tools.

- Better chip evacuation, vital for secure machining in internal operations.

- Longer tool life.

- Applications with coolant include boring, boring with chip breaker, boring with chip former, boring & profiling, square grooving, and pre-part off.

Vargus USA, VNE Corporation, 1149 Barberry Drive, PO Box 1698, Janesville, WI 53545, 608-756-4930, Fax: 608-741-7125, www.vargususa.com.