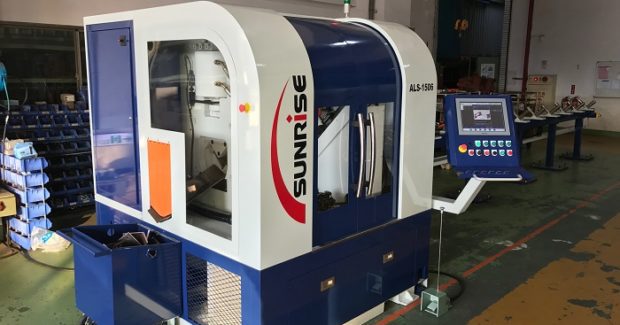

Fully Automatic Angle and Plate Processing System

The fully enclosed, fully automatic SUNRISE ALS angle processing system from Trilogy Machinery is a complete plate processing system that can punch and shear simultaneously and is driven by a powerful rack and pinion in-feed capable of handling up to 40 ft lengths of material at speeds up to 40 fpm.

Posted: September 17, 2017

In Booth A4848, Trilogy Machinery, Inc. (Belcamp, MD), the exclusive U.S. distributor for SUNRISE equipment, will introduce their new SUNRISE ALS fully automatic angle processing system, a complete plate processing system that is capable of both punching and shearing simultaneously. This fully enclosed system is driven by a powerful rack and pinion in-feed capable of handling up to 40 ft lengths of material at speeds up to 40 fpm. Standard features include pneumatic clamping, hydraulic plate hold-down, hydraulic stripper, touch-screen control and dual-punches. The ALS allows hands-free operation for the complete processing of angle up to 6 in x 6 in x ½ in. Its Dual Y-axis features a specially designed hydraulic punch driven on high speed linear rails, allowing the operator to punch across the entire width of angle. Pneumatic material guides, hydraulic punch strippers and quick-change tooling are standard.

Optional tooling allows quick change over to process flat bar from 2 in to 6 in widths and up to ½ in thickness, as well as adding a stamp/marking unit, all CNC controlled. The operation and programming are CNC controlled using a touch-screen display featuring operator-friendly programming with nesting capability. The operator simply positions the material on the in-feed table, initiates the pneumatic clamping, and the machine automatically processes, punches and shears the material. Trilogy Machinery offers 100 percent factory authorized service and support, as well as a full stock of spare parts and accessories at their north Baltimore location. Their sales force and fully staffed service and support department are all dedicated to providing the best customer service available.

https://youtu.be/f2GWAVPn3yk

Trilogy Machinery is also the exclusive North American Distributor for SWEBEND plate and angle bending rolls, WARCOM press brakes and LEMAS plate bending rolls, and the U.S. distributor for AKYAPAK bending rolls.

Trilogy Machinery, Inc., PO Box 70, Belcamp, MD 21017-1227, 410-272-3600, www.trilogymachinery.com.