Live Machine Production Data Anywhere, Anytime Via Email to All Devices

Using FactoryWiz Monitoring and DNC, Anywhere-Remote for Kitamura machine tools boosts production by collecting live unbiased shop floor data, creating baseline metrics and identifying process improvement opportunities.

Posted: September 21, 2017

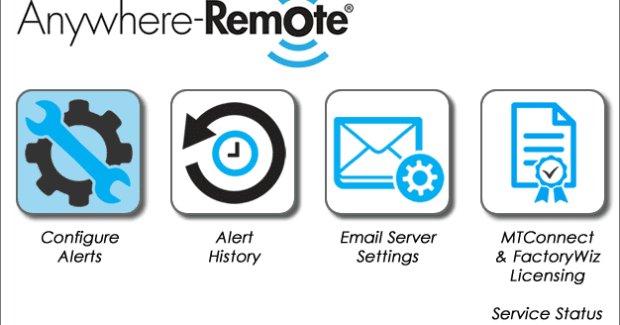

Refresh Your Memory, Inc. (San Jose, CA) announced a partnership with Kitamura Machinery of USA, Inc. (Wheeling, IL) on Anywhere-Remote®, a new IoT platform specifically for Kitamura machine tools that includes email status updates, machine monitoring software suites that range from basic plug-and-play packages to those that are customized to suit each individual user’s application, and MTConnect® ready adaptor (basic), all powered by and in partnership with FactoryWiz™ Monitoring and DNC.

Anywhere-Remote email status update technology allows the user to automatically receive live machine production data anywhere, anytime via email to desktop, smartphones and mobile devices based on pre-set variables. Machine production alarms, messages and cycle information can be received in real-time remotely via the Kitamura Arumatik-Mi® control. Machine status updates (running, idle, paused) can be generated for at-a-glance review of how the shop floor is performing, allowing for any errors or bottlenecks to be easily spotted and corrected. Period status events can be analyzed specific intervals by customer specified metrics. A variable change email component of the Anywhere-Remote email status update feature allows the end user to specify variables that they wish to monitor within their shop environment.

The Anywhere-Remote machine monitoring software suite (basic) boosts production by collecting live unbiased shop floor data, creating baseline metrics and identifying process improvement opportunities. Status and reports for Kitamura machining centers with Arumatik-Mi control are made available 24/7 on large display monitors (in common work areas), desktop monitors and all mobile devices from any web-enabled product anywhere in the world. The basic machine monitoring software suite includes configurable dashboard displays showing a variety of information in real time, providing visual manufacturing material to the shop floor, as well as manufacturing management, maintenance and quality departments.

Anywhere-Remote is also offered in a customized to suit option tailored to specific customer requests. “With traditional manufacturing models changing quickly, having the ability to gather real-time machine metrics and information is paramount in keeping the shop floor productive and organized,” said Ted Asano, the vice president of Kitamura Machinery of USA. “Having the ability to capture machine data through a variety of sources simplifies shop floor processes and helps determine where improvements or additions can be made to expand the company’s business. Being able to offer this software and monitoring suite solution across our Mycenter Machining Center line-up makes decision making easier for the end user.”

The Anywhere-Remote MTConnect Ready Adaptor (Basic) allows for machines to be readily and easily adapted to end users already running their own in house machine monitoring software protocols.