Winning the Battle Against Corrosion

To protect their steel plates and beams from corrosion, this shipbuilder turned to automated surface finishing that operates faster, improves blast and paint quality, handles larger plates and eliminates nearly all sources of emissions for a more efficient and environmentally friendly process – with little or no human involvement.

Posted: August 9, 2017

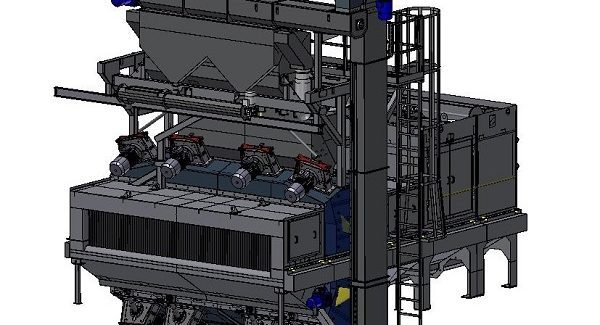

Every steel fabricating company faces the challenge of protecting their steel plates and beams from corrosion, because it is critical for producing quality, high-end products. To solve this problem, General Dynamics NASSCO (San Diego, CA), which specializes in the design and construction of auxiliary and support ships for the U.S. Navy, oil tankers and dry cargo carriers for commercial markets, turned to a Preservation Line from Rosler Metal Finishing USA, LLC (Battle Creek, MI) for a complete turnkey system that consists of a special transport system for loading steel plates, profiles and tubes, a pre-heater, a roller conveyor shot blast machine, an automatic paint booth with overspray separation, a paint drier with slat conveyor and a transport system for the next downstream operation.

Prior to this system, NASSCO was using a line that was built over 40 years ago. The new system is operating 30 percent faster, improves blast and paint quality, handles larger plates and eliminates nearly all sources of emissions, creating a more efficient and environmentally friendly surface finishing process. All of these components are interlinked for fully automatic operation with little or no operator involvement. Critical for the overall quality, productivity and cost efficiency of any preservation line is an equipment concept that is best suited for the respective workpieces with a technically sound design of the individual system components. This preservation line was custom engineered to process workpieces with different heights and widths. The parts consisted of steel plates, profiles and tubes that were covered in surface rust and scale prior to processing. These parts had a maximum dimension of 60 ft x 12 ft x 1.5 ft and maximum weight of 20 tons.

Jim Quagline, a project manager at NASSCO, worked with Rosler from the beginning on this project. The most significant challenge faced when planning this project was the coordination between the three parties involved – Rosler USA, Rosler Germany and NASSCO – being that each party is located in a different time zone, arranging meetings required extra planning. The distance also meant that NASSCO was only able to visit Rosler’s world headquarters in Germany once for inspection of the line before delivery, which is rare for a project of this size. “To sell a system without a visit onsite during the quotation phase was only possible due to great reliability and cooperation between them and us,” noted Steffen Reimann, a project manager for shot blasting technology at Rosler. “Weekly status reports and meetings continued through the planning and building phases of the project, assuring that we were kept in the loop regarding their progress.”

CUSTOMIZED WORKPIECE TRANSPORT SYSTEM

NASCCO had an existing crane storage system where the workpieces could be pulled from and delivered to the preservation line, but a delivery system did not exist. Rosler was able to design a shuttle delivery system that ran on tracks embedded in the ground and could deliver the parts directly to the intel of the roller conveyor from the storage system. At a speed of 12 fpm to 50 fpm and with a maximum capacity of 74,000 lb, this transfer shuttle provides effective and efficient delivery of the workpieces to the blast machine.

SIGNIFICANTLY HIGHER BLAST PERFORMANCE AND TURBINE UPTIMES

The blast chamber in this machine is made from manganese steel and is lined with overlapping, easily replaceable plates also made from manganese steel to provide extra durability inside the chamber. The shot blast machine itself is equipped with patented Gamma 400 G turbines. Compared to conventional blast wheels, these Gamma 400 G turbines produce a 15 percent to 20 percent higher blast performance with at least 100 percent higher uptimes. The turbines are placed in the upper and lower section of the blast chamber at an incline so that the blast media hits the workpieces at a defined angle. The angle of the blast turbines varies from project to project. Rosler makes a detailed check of all the parts that will pass through the blast chamber using a CAD system to allow for optimal blasting impact and minimal wear inside the chamber.

Compared to turbines hitting the workpieces at an angle of 90 deg, this inclined turbine arrangement results in a 15 percent to 20 percent higher de-scaling/de-rusting effect that significantly reduces the required cycle times. The integrated cleaning system for removing residual blast media from the parts consists of a rotating brush and a targeted high velocity air stream. It is equipped with a workpiece recognition system and automatic height adjustment that ensures the parts are leaving the blast chamber free of blast media and dust, a critical step for ensuring the required paint quality. At the same time, it eliminates the need for lengthy manual adjustment and minimizes the wear of the rotating brush. The capacity of the blast media cleaning and recycling system and dust collector are, of course, tailored to the machine size. Both can be placed on top of the machine, resulting in an extremely small overall machine footprint. Large doors allow easy access to the blast chamber for maintenance work.

MATERIAL-SAVING PAINT PROCESS WITH EFFECTIVE OVERSPRAY SEPARATION

A critical cost factor in any preservation line is the paint and primer usage. For this reason, the automatic paint booth is equipped with sensors precisely measuring the part dimensions. The system controls guide the paint gun movement, which precisely follows the workpiece contours to guarantee that the paint is applied at the required thickness and only when a part is under the spray nozzle. This results in significant paint savings and a minimum of overspray. Practically all solvent or water based paints with one, two or three components can be utilized. For applications requiring different types of paint, the automatic paint booth can be equipped with multiple independent paint delivery systems.

The cabin exhaust air system features an innovative trapezoidal, flow-optimized arrangement that prevents air turbulence and safely transfers the exhaust air mixed with paint mist to the standard dry separation unit, consisting of a patented brush pre-separator with slowly rotating brush rollers. The paint particles stick to the brush, dry, and fall to the bottom. This pre-cleaning stage is followed by a sinter-plate filter that reduces the residual dust load significantly below the legal requirements. The brush pre-separator reduces the filter load dramatically so that uptimes of around 15,000 hours for the sinter-plate filter can be achieved. Another benefit of this optimized air cleaning system is that minimal paint particles are deposited on the Teflon coated inner walls of the cabin, resulting in reduced cleaning times and lower operating costs.

Special steel slat conveyors are used to transfer the workpieces, which are still wet with paint, to the paint drier. They have only six contact points per 10 sq ft, keeping the risk of disturbing the paint at an absolute minimum. The drier is heated to 104 deg F and 180 deg F to eliminate the need for any additional energy input for the paint drying stage. Recirculating fans and special air guides ensure an even, all-around drying of the painted workpieces.

REGENERATIVE OXIDIZER USED TO REMOVE HARMFUL SOLVENTS

In order to meet the strict air quality requirements of California, Rosler used a unique regenerative oxidation system to process the exhaust from the painting process before it is released into the atmosphere. The exhaust contains harmful solvents which must be removed. This is achieved within a three-chamber system that features a regenerative thermal recovery process that occurs on ceramic beds. The polluted air is channeled from the painting process into the first chamber, where the air is warmed up and the VOCs are oxidized. After leaving the first chamber, the air then passes through the combustion chamber, where a steady temperature is maintained by the burner. It then passes through the second chamber, where the air is cooled by a ceramic bed before passing into the third chamber, where the air is put through a washing process. The resulting clean air is then sent through the stack.

General Dynamics NASSCO, 2798 Harbor Drive, San Diego, CA 92113, 619-544-3400, Fax: 619-544-3541, nassco.com.

Rosler Metal Finishing USA, LLC, 1551 Denso Road, Battle Creek, MI 49037, 269-441-3000, Fax: 269-441-3001, [email protected], www.rosler.us.