Twice the Cutting Speed on Thick Plates

The new Highspeed and Highspeed Eco nozzles and flexible TruLaser 3030 fiber and TruLaser 2030 fiber with LiftMaster Shuttle from TRUMPF allow for a nearly twofold increase in sheet throughput compared to standard cutting.

Posted: August 8, 2017

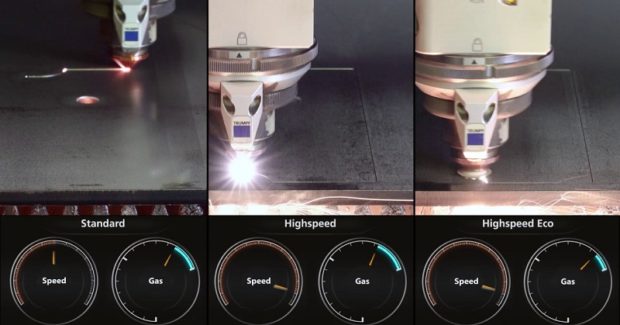

New processes on 2D laser cutting machines from TRUMPF Inc. (Farmington, CT) lead to 70 percent reduction in cutting gas and doubling of sheet throughput. The company has introduced their newly designed Highspeed and Highspeed Eco nozzles that boost the feed rate by up to 100 percent for solid-state laser machines that employ fusion cutting with nitrogen. With this new technology, the piercing process is faster and laser power does not need to be increased. These new cutting processes allow for a nearly twofold increase in sheet throughput compared to standard cutting. Less cutting gas is used due to the nozzle’s innovative design. The Highspeed process requires 40 percent less nitrogen on average, while the Highspeed Eco is 70 percent less.

In fusion cutting, gas, under relatively high pressure, blows molten material out of the kerf, incurring high operating costs. Flame cutting utilizing oxygen is commonly used for mild steel, especially for relatively thick sheets. The advantage of low gas costs is offset by oxidized cut edges that often need to be reworked. By contrast, the Highspeed and Highspeed Eco processes are faster and use less gas to greatly increase the cost-efficiency of fusion cutting mild steel with nitrogen. In addition, the scope of applications is now broader for 8 kW lasers used in fusion cutting. The laser can now fusion cut sheets as thick as 0.5 in instead of 0.4 in as in the past.

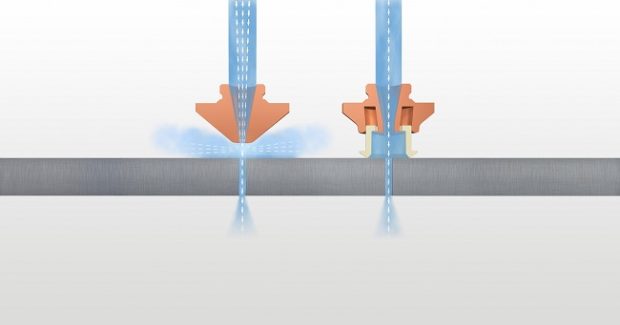

The Highspeed process makes use of a bi-flow nozzle. Some of the cutting gas passes through the center of this nozzle, as does the laser beam. The rest forms a secondary flow around the principal flow to concentrate it onto the kerf, expelling molten material more efficiently. The Highspeed Eco process relies on a patented nozzle fitted with a sleeve that forces the gas directly into the kerf, ensuring that little or no gas flows off to the side. While this moving sleeve glides across the material during fusion cutting, the nozzle remains 0.06 in from the sheet surface. This ensures that the nozzle can effortlessly withstand any spatter generated during piercing which accelerates piercing and minimizes the risk of damage.

Highspeed and Highspeed Eco can be used for fusion cutting of mild steel and stainless steel sheets at least 0.16 in thick. Additionally, just one nozzle is needed for the entire material thickness range in these cases, which makes mix-ups less likely and shortens setup times. Cut edges exhibit low surface roughness and a high-quality, consistent look. The Highspeed Eco and Highspeed can now be used on machines in the TruLaser Series 5000 that are equipped with an 8 kW solid-state laser, and will be available soon for use with 6 kW solid-state lasers. The Highspeed process is featured on machines in the TruLaser Series 3000 fitted with a 6 kW solid-state laser. Many relatively new machines can be retrofitted with these processes.

The company also offers the TruLaser 3030 fiber, a highly flexible, productive and universal machine for 2D laser processing across a wide range of material types and thicknesses. This machine is available with up to 6 kW of power with standard BrightLine fiber that enables fabricators to cut steel, stainless steel and aluminum up to one inch with exceptional quality. The machine is based on a simple operating and maintenance concept and offers numerous options to enhance versatility. Its universal cutting head works together with BrightLine fiber to make it easy to process all sheet thicknesses by eliminating the need to change the processing head between applications. The adjustable and ergonomic control panel features intuitive touch operation to guide users through the program functions. In addition, the TruLaser 3030 fiber is built with the highest regard for safety. The enclosed frame with laser safety glass protects the operator yet enables them to safely monitor the entire process.

For job shops that run up to three shifts per day, as well as for first-time laser users looking to add laser cutting capabilities to their business, TRUMPF offers the cost-efficient yet productive TruLaser 2030 fiber with LiftMaster Shuttle. This machine features an energy-efficient and fully integrated 4 kW TruDisk laser that enables flexible and economic laser processing across a variety of materials and thicknesses. With a 60 in x 120 in working range, the TruLaser 2030 fiber achieves optimum energy efficiency with minimal space requirements. The machine is controlled by a user-friendly touch screen interface that graphically displays the program and all essential information to keep operators in control, regardless of their experience level. These and other features make this system the ideal choice for fabricators in need of productivity and process reliability at competitive investment and operating costs.

In order to boost productivity even further, the innovative LiftMaster Shuttle is the most flexible automation system for loading and unloading available in this market segment. It allows users to run production with either the standard pallet changer or with the shuttle for the added capacity to support complete lights-out production and overnight runs. This fast and flexible automation system is available in a variety of configurations to best match the user’s layout and material flow requirements.

TRUMPF Inc., Farmington Industrial Park, 111 Hyde Road, Farmington, CT 06032, 860-255-6104, www.us.trumpf.com.