Never Chase Non-Conformance Without Adequate Data Again

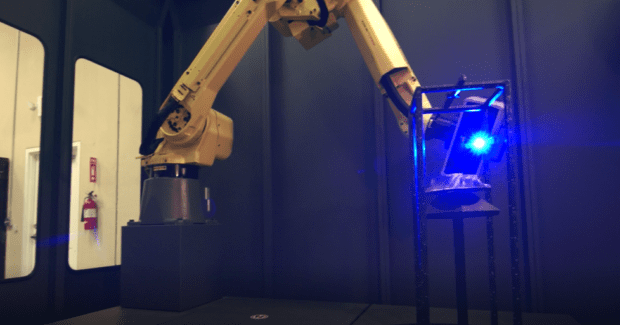

A complete digital thread of state-of-the-art dimensional inspection services from ETS Power Group takes on the tough jobs using novel and unique techniques that can precisely inspect the most complex and challenging parts.

Posted: August 12, 2017

In Booth 1631, ETS Power Group, Inc. (Stuart, FL) offers a complete digital thread achieved through state-of-the-art dimensional inspection services and a team of highly trained engineers and technicians that work closely with users to understand their needs and develop the most cost-effective means to achieve 100 percent satisfaction:

- First article inspections in accordance with AS9102.

- Production inspections of high volume parts, at the user location or theirs.

- In-process inspections of development parts.

- Trend analysis and SPC assessments.

- Gage R & R studies and assessments.

- Tool & Die verification.

ETS maintains quality certifications to ISO9001 and ISO17025 standards and utilize state-of-the-art equipment and techniques to ensure that user requirements are achieved and maintain a statistical database of every dimension. They have earned a reputation for taking on the tough jobs as leaders in driving blue light inspection technology to new heights of capability with novel and unique techniques that allow them to precisely inspect the most complex and challenging of parts. Being early adopters of blue light inspection technology, they have mentored others to apply and adopt the technology to inspection of complex geometry on many different types of parts. Their reports are a tool to debug current manufacturing processes and an absolute quality check on finished products, complete with data analysis to enable manufacturing to be world class and ensure that users won’t turn back to the days of chasing manufacturing non-conformance without adequate data.

ETS Power Group, Inc., 3321 SE Gran Park Way, Stuart, FL 34997, 772-781-3883, www.etspower.com.