Make Your Mark

Whether you mark your parts for identification, ornamentation or post processing, there are several options to consider. Regardless of the purpose of the mark or the material to be marked, there is a product marking system to fulfill your needs. Here are several different ways for you to make your mark.

Posted: August 12, 2017

Part marking has become an integral part of the manufacturing process, from managing and streamlining production within the shop to traceability of a part for its lifetime. Visual indicators can be simple, such as those used for basic part identification, bending instructions or post processing operations, or those that are more complex, including bar codes, data matrix codes, and ornamental designs. Whether for branding, functional use or traceability, value is created along with the mark. By knowing what your machine can do, you’ll make your mark – economically and just the way you want it.

PUNCHING/FORMING

A punching machine offers different solutions for part marking and enables fabricators to eliminate a secondary processing step. One option is a high speed dot matrix. A punching machine can generate marks at the rate of one inch per second and is able to fabricate nearly any font size, character or shape, given the geometry that is achievable with a dot matrix. This type of mark will remain visible even if the material is painted or coated further down the production line, which is highly desirable for many applications.

A second option, scribing, uses a tool with a special diamond tip to scratch the surface of the material. Although the depth of the mark is limited, this is a highly flexible solution for engraving and produces a very nice result. This is often the best punching system when the mark will be visible to the end user. Another option, solid stamp marking, is best when a basic and repetitious mark is required. A logo or a few characters are locked into place on a tool and a single strike is able to quickly and efficiently produce the desired effect. Although this solution is limited because there is no versatility in its design, it is possible to control the depth of the mark when embossing or stamping.

With hard tooling characters, fabricators have greater flexibility to mark any combination of numbers or characters across multiple tool setups. While the size and font of the mark must be predetermined, the result is attractive, flexible, and very fast to produce. Some manufacturers of punching machines also offer tools with special line and arc segments that are designed to be perfectly and automatically arranged to create any alpha or numeric character. Marks can be achieved at a rate of two characters per second. Although the result is less aesthetically pleasing than with tools that use dedicated letter and numbers shapes, this solution is less costly due to the reduced number of punching tools required and it can produce a wider range of marks.

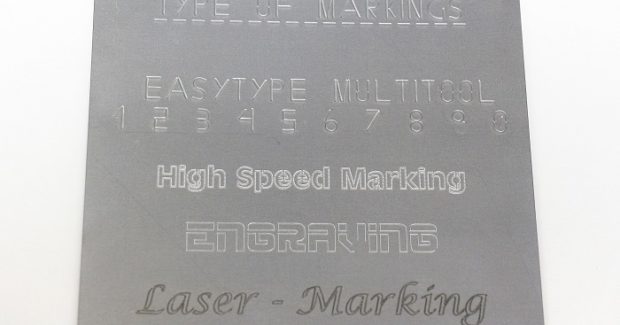

2D LASER ETCHING

Laser etching with a 2D laser cutting machine is a flexible way to produce functional visual indicators on a wide range of materials. Similar to marks produced on a punching machine, marking on a laser cutting machine eliminates the need for a secondary marking step downstream. When a laser cutting system is used to mark a part, the operator has control over the etching depth. This method offers the flexibility to simply score the material or to penetrate the material more deeply, depending on the desired result. In addition, the laser machine offers the possibility to adjust aspects of the mark by manipulating the laser parameters. For example, by using shop air or oxygen for the assist gas it is easy to produce a mark with high contrast when etching stainless steel. It is also possible to program the laser beam to produce a series of hatch marks. This enables the fabricator to fill in larger or more decorative marks, or to achieve better contrast in reflective materials.

With basic knowledge of the laser cutting machine and an understanding of the principles of speed and laser power, it is easy to create a mark that is highly aesthetic and useful across a wide range of materials.

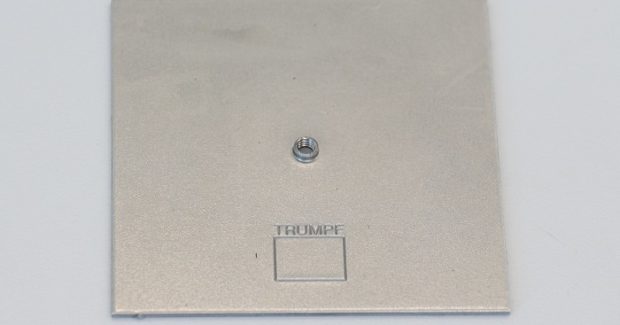

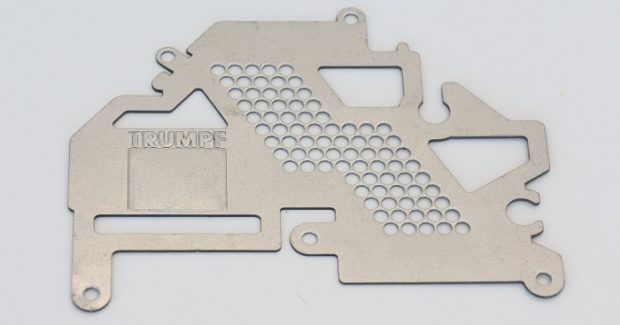

MARKING LASERS

There is a wide range of options when it comes to a dedicated laser marking system, and most sheet metal fabricators will gravitate toward a supplier who can provide a robust industrial solution. They are available as standalone systems or can be integrated into production lines to grant the fabricator a higher level of productivity, quality and precision in marking. These industrial laser marking systems easily produce any desired mark, including complex pictures or graphics, data matrix codes, and logos, and they do so in a fast and economical way. This type of processing is usually gentle on the base material – an essential factor for many manufacturers that supply the medical, aerospace, food service, or similar industries. They can be programmed to engrave, ablate or anneal metals, as well as mark plastics, ceramics, glass, silicon and inorganic materials. Surface preparation, such as for welding, is also possible when the right laser system is used.

Whether you are marking your parts for identification, ornamentation or post processing, there are several options to consider. Regardless of the purpose of the mark or the material to be marked, there is a product marking system to fulfill your needs. From a laser marker to laser etching with a 2D laser, or even marking with a punch machine, there are several different ways for you to make your mark.