How to Optimize Grinding Time and Cut Rates on the Toughest Materials

Ideal for heavy stock removal, edge chamfering, weld blending, grinding, and surface preparation and finishing, Tiger Ceramic, Zirc and Aluminum, and Wolverine Zirc and Aluminum Oxide resin fiber discs from Weiler Abrasives provide aggressive cut rates and smooth finishes on tool steel, aluminum and any material in between.

Posted: August 11, 2017

In Booth B23058, Weiler Abrasives Group (Cresco, PA) expands their resin fiber discs (RFDs) offering to include five new products for varying performance requirements: Tiger® Ceramic, Zirc and Aluminum, and Wolverine Zirc and Aluminum Oxide. These discs are designed to provide an aggressive cut rate and a smooth finish on tool steel, aluminum and any material in between. The products are ideal for heavy stock removal, edge chamfering, weld blending, grinding, and surface preparation and finishing. Featuring advanced grain formulas, along with a superior design that minimizes loading, glazing and grain stripping, the new Tiger and Wolverine resin fiber discs include heavy duty vulcanized fiber backing to withstand the toughest jobs. In addition to standard 7/8 arbor discs, a quick-change hub option reduces downtime and eliminates the need for tools and disc nuts.

As part of this maximum performance line of RFDs, Tiger Ceramic features an advanced, self-sharpening ceramic grain that delivers greater stock removal with a finer scratch pattern, along with a superior life and cut rate. A top coat grinds cool, reducing heat discoloration and loading. This disc is ideal for work on armored steel, stainless and tooled steel, Inconel and more, in applications requiring high removal rates.

Tiger Ceramic is a maximum performance line of cutting, grinding and combination wheels that delivers a superior combination of product life and cut rate to help users maximize time on the job in a wide range of metal fabrication applications. The durability of this disc means more cuts and more material removed over the life of the wheel. In validated end user testing, this ceramic disc provided 25 percent to 40 percent longer life compared to other ceramic discs on the market.

“Tiger Ceramic discs effortlessly remove material while a hard bond keeps working longer, for unmatched product life,” said Rick Hopkins, a senior product manager of metal fabrication at Weiler Abrasives. “For anyone that puts a premium value on getting work done faster and optimizing wheel usage, this delivers.” Ceramic grains utilize a crystalline structure designed with millions of fracture points that self-sharpen at a higher rate than other grains. The result is a higher material removal rate, faster cutting speeds, cooler grinding and reduced friction at less pressure, which reduces operator fatigue. Lower temperature and less friction also reduces heat discoloration of the work piece, and translate to a smoother cut and less kickback during operation of cutting wheels.

With longer product life, a reduction in downtime for wheel changeover, and cut rate and performance that help get jobs done faster, Tiger Ceramic helps provide an overall lower cost of use. Available in Type 1 and Type 27 styles, these discs are a contaminant-free and worry-free tool that can be used on stainless steel, Inconel, high nickel alloy, titanium and armored steel.

Tiger Zirc and Aluminum are part of this high performance line of RFDs. Tiger Zirc leverages a unique blend of self-sharping Zirconia Alumina and Ceramic Alumina grains for fast cut rates, exceptional consistency and a long life. This makes them ideal for improving productivity and cost savings on light to heavy pressure grinding applications on materials such as steel, stainless steel and cast iron. Tiger Aluminum provides a non-loading solution for grinding aluminum and other non-ferrous metals. A top coating releases lubrication when grinding to reduce heat build-up and allow the metal to shed for higher cut rates, longer life and a superior finish. Wolverine Zirc and Alumina Oxide RFDs are designed to deliver fast, clean cut rates and consistent performance on general purpose applications, at a great value.

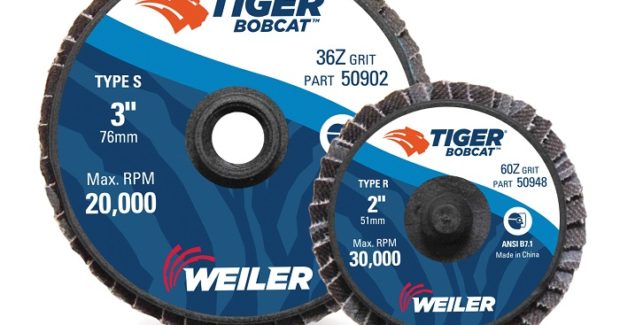

The company has also expanded their Tiger BobCat mini flap disc offering, along with design improvements to enhance performance and extend product life. The enhanced design of these mini flap discs offers one and a half times greater life compared to the original BobCat flap discs, lowering the total cost of use. Tiger BobCat mini flap discs are ideal for grinding and finishing jobs in hard-to-reach areas, and for weld blending or edge chamfering in metal fabrication. When the application calls for aggressive grinding, these flap discs are designed to shed cloth and expose new grain, delivering a consistent, aggressive cut rate. They remove three times more material over the life of the disc than a comparable blending disc, and operate best on steel, stainless steel, structural steel and cast iron.

The expanded Tiger BobCat family of products now features a threaded button “R” mount, as well as the current threaded arbor “S” mount to fit the most popular styles of back-up pads and offer greater versatility. Available in angled and flat styles, these discs are designed for use on right angle die grinders to provide smooth grinding and improved conformability in tight areas. Both types of wheels are available in 2 in and 3 in diameters.

Weiler Abrasives Group, One Weiler Drive, Cresco, PA, 18326-0149, 800-835-9999, www.weilerabrasives.com.