How the Science of Abrasives Yields the Art of Performance

Take a closer look at how new developments in abrasives are significantly improving grinding wheel performance and user ergonomics.

Posted: August 12, 2017

On average, the cost of abrasives for large metal fabrication firms is less than two percent while the total cost of grinding and finishing is 10 percent to 15 percent. Cutting abrasive cost may seem attractive, but the reduction of labor costs presents the real upside for the end user. However, there are other less obvious benefits that some grinding wheels provide over others. Grinding wheels for right angle grinders used in metal fabrication have had dramatic increases in performance over the last 20 years. Some of the improvements have come in bond technology and manufacturing tolerances, but the majority of the performance increases have resulted from advances in abrasive grain technology.

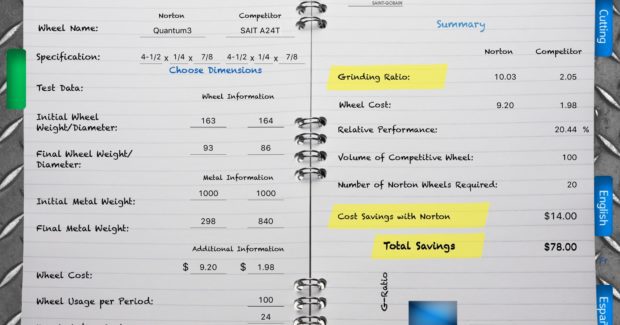

One example of how a shop can lower their abrasive usage is shown in Figure 1, where a large fabricator of cast parts reduced their wheel usage from 100 competitive aluminum oxide wheels to 20 Norton ceramic alumina wheels to accomplish the same job. When adding in the cost of labor to change wheels and a reduction in the time spent grinding, the total cost of labor for the job was reduced by 80 percent (see Figure 2). These are the measurable savings that can be realized at any shop or job site. So why are manufacturers with labor rates at $24 per hour and upward (with fully loaded cost for employees) still not using the best performing wheels? One answer may be perception: abrasives are still seen as a tertiary expense for the operation.

ABRASIVE GRAIN OVERVIEW

Abrasive grains are the key component of the depressed center wheel. They are the “cutting tool” of the product and it is important to match their performance characteristics with the needs of the job to ensure right choices for the user.

Aluminum Oxide (AO)

Until the mid-1970s, aluminum oxide (AO) was the only choice for grinding all types of metal. Aluminum oxide is a strong, blocky-shaped abrasive grain (see Figure 3). While the initial edge of the grain is sharp, it rapidly dulls. With broad cleavage lines, the grain continues to wear until enough pressure is created to fracture the grain and create a new sharp cutting edge. When the fracture does occur, a large percentage of the grain is lost. The result is a slow cutting abrasive where only 25 percent of the utility of the grain is realized.

Zirconia Alumina (ZA)

In the late 1970s, zirconia alumina (ZA) grain was developed through a fusion of zirconia and aluminum oxide to provide a sharp, tough grain that would still be “friable” enough to breakdown in portable applications. Zirconia alumina grain is a harder, sharper grain that has been engineered for controlled fracturing. The combination of the harder, sharper grain and better utilization of each grain provided a 50 percent improvement in cut rate and three times the life over aluminum oxide (see Figure 4). This technology was first commercialized in depressed center wheels in 1980 with the introduction of our Norton NorZon products.

Ceramic Alumina (CA)

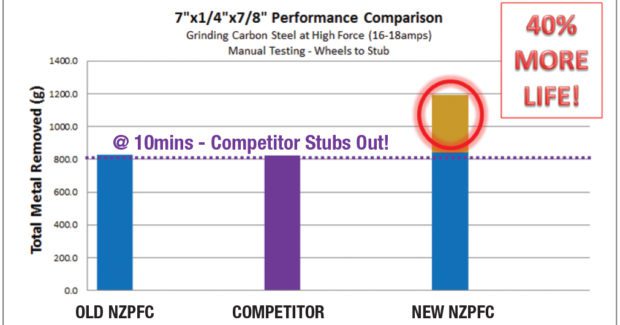

This technology, created in the 1990s, is based upon doped alumina sol gels. The key characteristic of these high performance abrasives is the unique combination of hardness and toughness that is essential for controlling micro-fracturing of the grains, which is crucial for providing a continuous supply of sharp cutting edges during grinding that results in raising the utilization of each grain to over 80 percent (see Figure 5).

Grain shapes have become more sophisticated with recently introduced precision shaped grain (PSG). In side-by-side studies, irregular shaped ceramic grains cut through the workpiece with smooth almost effortlessly ‘gliding’ motions. Precision shaped grains, on the other hand, were perceived to be ‘rougher’ and required the operator to adjust his stance. This situation stems from the fact that precision shaped grains break down to form geometric shapes that are significantly less efficient in cutting than the original geometric form. Irregular shaped grains fracture and wear to form more irregular shaped geometries. This consistency of irregular starting and intermediate fractured geometries provide a more uniform cutting action throughout the wheel life and hence a better overall grinding experience. Additional benefits of these high performance abrasives can be:

- Less machine maintenance.

- Less metallurgical damage/improved part integrity.

- Less operator hardship/fatigue.

RESIN BOND OVERVIEW

Premium performance abrasive depressed center wheels are constructed using a precisely engineered iron, sulfur and chlorine-free resin technology to provide a uniform abrasive distribution throughout the wheel. This unique bond was designed for retaining the grains long enough during and after grain fractures. This subtle but powerful bond characteristic enables both excellent cut rates and exceptional wheel life. Non-optimal bond technologies can result in either retaining the grain too long or not long enough. In the first scenario, the fractured grains are retained in the wheel and result in swarf build-up on the wheel face, followed by glazing, slower cutting and, ultimately, more effort by the operator to force the cut. In the second scenario, fractured grain is released prematurely and results in a fast cut, but with a very short wheel life that requires frequent wheel changes and downtime that generate additional operating costs.

Other factors, including machine horsepower, air supply (pneumatic only), grinding angle, surface contact area and type of material being shaped or cut, also play roles in the abrasive grain-to-resin bond ratio. However, it is paramount that the abrasive manufacturer work on improving bond technology, in conjunction with advancements in abrasive grain, in order to maximize the total performance of the depressed center wheel.

FIBERGLASS REINFORCEMENT OVERVIEW

The third component of every depressed center wheel are the fiberglass reinforcing layers that are required for safety standards due to the fact that the wheels are used on a portable hand-held power tool. The standard orientation of the fiberglass reinforcing is shown in Figure 6. Two and a half layers are used to meet ANSI B7.1 standards. On certain wheels, especially for rugged applications like foundries, three full layers are used. Grinding with these wheels can be done on the face or the periphery of wheel showing 2-1/2 layers.

For ¼ in wheels where the grinding is only done on the face of the wheel, a fine, hard back-finer grit mixture in the top half of the grinding wheel can be offered to limit premature shedding or “spalling” and allow for a smoother grinding action from the periphery to the hub.

The correct orientation of the reinforcing layer is required for safety. Choosing the fine, hard back can help improve grinding performance by reducing premature spalling or spitting (loss of grain) that is especially critical when using premium abrasives, such as our Norton NorZon or blended Ceramic Alumina NorZon.

THE SCIENCE OF ABRASIVES YIELDS THE ART OF PERFORMANCE

Our Norton Quantum3 is one example of the “science of abrasives yielding the art of performance” in grinding wheels: it grinds faster, with less pressure, to significantly increase production while using fewer wheels. Its industry-best metal removal rate is gained from the larger grit size of our proprietary grain. Bond is matched to grain to produce the highest level of performance: metal removal rate and wheel life. This new bond contains a unique combination of fillers and bonding agents that allow for much better mix quality in manufacturing. The better mix keeps the individual grains from clumping to one another, allowing more even wear of the bond and abrasive structure because of the more homogenous distribution of grain within the wheel and better adhesion of the grain to bonding materials.

This design is also contaminate-free, as it contains <0.1 percent iron, sulfur or chlorine, for rust-free and corrosion-free results that will not contaminate stainless steel. Other advantages include:

- Smoother Feel. Wheels that use a type of ceramic PSG tend to generate a different, variable operating feel than the Quantum3. This variable feel is characterized as vibration or jumping on the workpiece. Our ceramic grain is a more robust, consistent grain due to the manufacturing process and is more rounded than pointed. This wheel design permits an easier, smoother feel during grinding, promoting a faster cutting action at reduced pressure, for substantially longer wheel life.

- Better Control. Typical precision shaped grains do not allow sufficient grinder/grinding wheel control during the grinding cycle when used in different directions. More effort can also be required to grind with precision shaped grains on the edge, so that the operator has less control and may need to exert more energy/body support to keep the grinder under control. These wheels produce no grabbing or digging on the workpiece when used in any direction. They glide through the workpiece while removing metal, producing a very smooth grind at a faster rate for less downtime and reduced landfill waste due to fewer wheels used.

- Improved Operator Comfort. The Quantum3 wheel is exceptionally free cutting, enabling the wheel to boost the amperage on its own with little or no pressure, due to the unique mix of bond and abrasive. The operator doesn’t have to apply excess pressure to get the job done when compared to using lower performing products, resulting in reduced hand fatigue from less cutting vibration.