How a Small Shop Can Automate Their Quality Processes

Ideal for aerospace, automotive, medical, oil and gas, and other industries, the Inspection Manager QMS design and manufacturing inspection platform from HighQA enables shops of any size, small to enterprise, to automate their entire internal and external manufacturing and quality processes by integrating design, manufacturing, and inspection requirements.

Posted: August 12, 2017

In Booth 1534, HighQA™ Corporation (Keyport, NJ) will display their line of highly successful manufacturing and quality software systems for OEMs and suppliers. Their comprehensive QMS design and manufacturing inspection platform enables shops of any size, small to enterprise, to automate their entire internal and external manufacturing and quality processes. This platform integrates design, manufacturing, and inspection requirements to provide the most intelligent and trusted quality management available for aerospace, automotive, medical, oil and gas, and other industries. It is designed to assist in converting a quality department into a profit center through seamless integration with design and manufacturing processes, cost cutting, eliminating user errors, taking corrective and preventive measures, improving customer satisfaction and supporting user goals of being awarded and/or successfully maintaining their ISO/TS 16949:2009, ISO 9001:2008, ISO 14001:2004, QOS, APQP, and other standards.

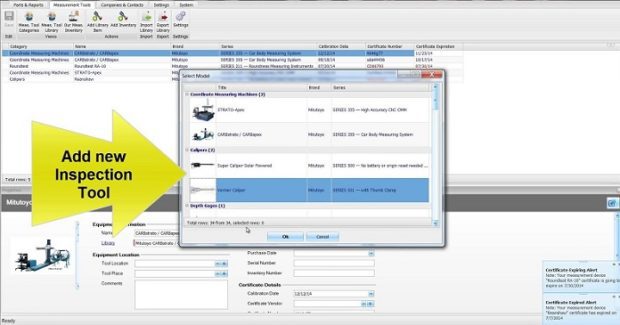

Inspection Manager™ (IM) is an integral part of the QMS platform that automatically extracts manufacturing and inspection requirements from any PDF drawing or 2D blueprint and instantly creates a complete bill of characteristics in a data format, including automated ballooning and GD&T extractions. IM will automatically read inspection results from all CMMs and other inspection tools and automatically generate all the required report forms (FAI, PPAP, and others) to help users seamlessly manage project details, expedite delivery times, cut costs, and increase customer satisfaction. Since a manual process is no longer necessary, its cutting edge intelligent manufacturing and 2D inspection extraction ensure that GD&T specifications are correctly identified and located.

The Quality Inspection System ensures that GD&T specifications are automatically and correctly recognized, helping users avoid unnecessary plan revisions and re-inspections due to miscalculations or incorrect assumptions. IM’s automated GD&T recognition is one of the many unique features of this high-powered software system. IM Explorer™ is an innovative digital mobile data collection application that enables users to convert their underperforming and error-prone data collection process into a smart, digital, paperless process. Explorer runs on wirelessly connected mobile devices and provides a friendly, easy-to-use touchscreen interface. Explorer has a small footprint and offers ultimate mobility for convenient remote/shop floor inspection data collection. The application is IT- and network-friendly and is compatible with standard device management, enterprise security, domain policy, and other IT needs.

HighQA Corporation, 135 First Street, Suite 3B, Keyport, NJ 07735, www.highqa.com.