Cloud Machining Takes Center Stage

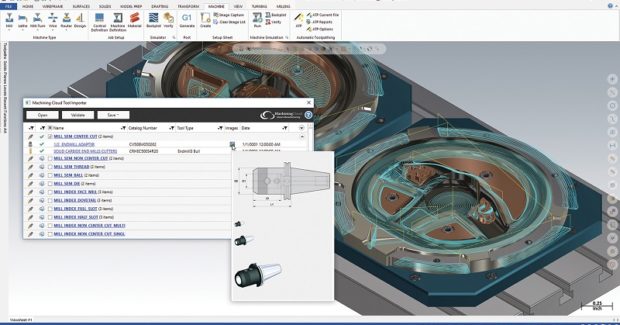

Users of Mastercam 2018 now have direct access to complete, up-to-date cutting tool product data from cutting tool manufacturers that are available on the MachiningCloud, and can quickly filter possibilities down to an optimum solution for a given workpiece.

Posted: August 1, 2017

In Booth 1715, CNC Software, Inc. (Tolland, CT) and MachiningCloud, Inc. (Camarillo, CA) jointly announce that with the release of Mastercam 2018, Mastercam is now connected to MachiningCloud, thereby providing users access to the cutting tool knowledge and product data available within the cloud. This partnership provides CAD/CAM users access to cloud cutting tool product data from within Mastercam. They now have direct access to complete and up-to-date cutting tool product data from the leading cutting tool manufacturers that are available on the MachiningCloud. With this completed connection, key benefits are available to users that include:

- Search for tools from multiple manufacturers quickly in one place.

- Access manufacturer’s expert cutting tool recommendations.

- Quickly filter a universe of possibilities down to an optimum solution for a given workpiece.

- Import the selected product data into Mastercam for programming.

- Utilize the 3D models for simulation and 2D drawings for documentation.

“Our mission is to bridge the gap between physical cutting tools and digital shop software, and streamlining the programming process to save time and increase accuracy,” says Christophe Rogazy, the director of product management for MachiningCloud. “By bringing together valuable cutting tool data and knowledge in one application, this simplifies the cutting tool search process and gives users many more options and helps them make better tooling decisions. By joining forces on MachiningCloud, Mastercam ensures greater and more seamless flow of information throughout their users’ shops.”

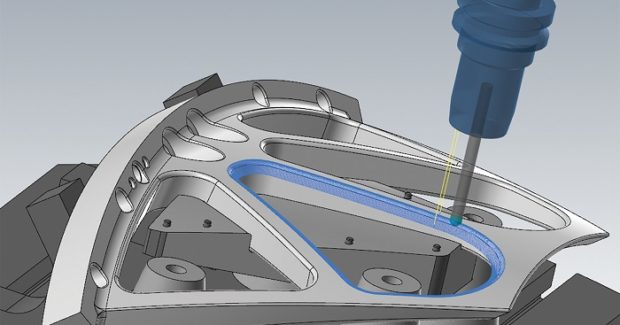

“Accurate tool definitions are a critical factor in achieving safe and efficient toolpath motion,” added Says Rich Taft in product development at CNC Software. “MachiningCloud offers a wide variety of tooling options that make it easy to import well-defined tools into Mastercam.” Mastercam 2018 brings a new suite of programming tools focused on delivering speed, automation, and efficiency for all machining jobs. The software offers new 2D/3D Milling features, Design improvements, powerful turning and Mill-Turn enhancements, and so much more. Stock awareness has been added to select 2D toolpaths and allows tool motion on the top, bottom, or both values of the stock. This provides a safer and more optimized tool motion. Users can also optimize finish passes based on your rough stock, giving you more efficient and safer tool motion.

The workflow for all 3D High Speed toolpaths has been streamlined and gives users fine control over exactly where to cut. High speed Hybrid toolpaths now offer smoothing controls and deliver a finer finish, requiring less handwork. For users that work with stringy materials, such as aluminum or plastic, the new Chip Break control prevents problems by allowing them to set length and time conditions, retract, and dwell options. Mill-Turn machine definitions now contain tailstock and quill components, tailored to their machine.

Shops can model their own designs, but they also get in models that need to be corrected or prepped for machining. CAD functions are designed for the machinist. Angle Sweep improves the creation of more complex wireframe functions and when creating or editing primitives, there are now on-screen sweep and rotate controls which can snap to the AutoCursor positions of existing entities. To make Roll and Unroll results easier to predict, Seam Control lets users visually rotate a seam to see how geometry will respond, as well as snap to AutoCursor positions. Hole Axis makes it easier to work with a large number of holes, especially holes with matching diameters that are selected as a group. Also available in the Mastercam 2018 release is:

- My Mastercam gives you access to your profile, Mastercam social media outlets, your Reseller information, the Mastercam Forum, and other helpful information.

- Streamlined workflow with improved plane management, level and geometry control, toolpath analysis and more.

- Model Prep and Solid Model enhancements such as Multiple Undo/Redo for up to twenty-five functions and Solid Sweep has more options and controls than ever.

- The Collision Control and the Multiaxis Link Safety Zone pages for Multiaxis toolpaths have been redesigned.

- Common direction has been added to the Tool Axis Control page for Multiaxis toolpaths and keeps the tool at a uniform tilt angle to reduce tool and machine motion.

- And many other productivity improvements across the entire product.

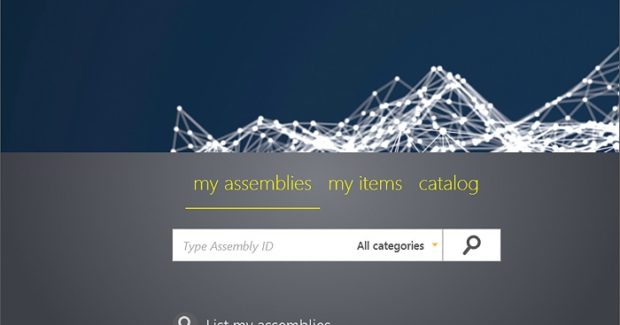

CNC Software, in partnership with Sandvik Coromant (Fair Lawn, NJ), also announced the integration of the CoroPlus ToolLibrary into the new release of Mastercam 2018, which allows CAD/CAM users to save significant time searching for desired tools and building 3D tool assemblies that can be brought directly into Mastercam via the ISO 13399 data format. Exclusive to Mastercam, a new set of turning strategies automate toolpath generation and support for CoroTurn® Prime inserts and the PrimeTurning™ method to provide superior metal removal rates, productivity gains of over 50 percent, and increased tool life in a variety of materials. Mastercam developers worked closely with Sandvik Coromant product management to let users import 3D tool assemblies directly into toolpath operations. Users benefit from having the correct tooling for the material and for the type of machining operation, plus an accurate, 3D model that can be used for visualization and collision checking in addition to the time savings.

“In the past, users had to search through thousands of catalog pages and cross-reference multiple sources to create the tool assemblies needed to machine their parts,” said Dave Boucher, the director of product for CNC Software. “Now they can save significant time and effort by quickly searching and building virtual 3D tool assemblies using the CoroPlus ToolLibrary interface and import them directly into Mastercam when they program their parts. As a digital database and part of a user’s digital machining environment, they get instant access to the latest cutting tool data and technology available.”

“The tool library system allows users to put the different tool items together – for example, a milling cutter, the inserts, and the holder – and then have an accurate representation of the actual tool,” stated Pernilla Lindberg, the product manager of process planning at Sandvik Coromant. “To partner with and have the support of a leading CAM (computer-aided-manufacturing) software provider such as CNC Software and Mastercam, we are excited to expand the digital machining environment and foster the standardization of cutting tool data.”

CNC Software, Inc., 671 Old Post Road, Tolland, CT 06084, 860-875-5006, www.mastercam.com.

MachiningCloud, Inc., 1130 Avenida Acaso, Camarillo, CA 93012, 805-437-4171, [email protected], www.machiningcloud.com.

Sandvik Coromant US, 1702 Nevins Road, Fair Lawn, NJ 07410-0428, 201-794-5000, Fax: 1-201-794-5157, www.sandvik.coromant.com.