Tool Holding Plays an Important Role Where Chips are Flying

When Pilatus Aircraft installed new manufacturing systems for machining structural parts made of aluminum, they relied on tool holders and shrinking and balancing machines from Haimer to achieve the desired surface quality and precision during high speed milling operations.

Posted: July 14, 2017

Whenever someone in precision machining talks about flying, one thing is typically brought up: chips. This has never been more true at Pilatus Aircraft Ltd (Stans, Switzerland), the only Swiss aircraft manufacturer, where everything generally revolves around the topic of “flying,” including the important role of machining structural parts used in their aircraft. In 2016, the company invested in a completely modernized volume-machining system to further improve the quality and efficiency of their production. The core elements are two new flexible manufacturing systems that run with full automation and guarantee the highest quality in a stable process.

In this high precision environment, fine-balanced tools are absolutely necessary. “Only the high balancing grade of the complete tool assembly, balanced on one of our balancing machines together with our tool holders, can guarantee vibration-free machining and surfaces without any chatter marks,” points out Walter Duss, the director of milling at Haimer GmbH (Hollenbach, Germany). “The high run-out accuracy significantly increases the lifetime of the spindle and tools.”

“Since we are working with many different parts that are extremely thin with wall thicknesses (≤ 1.2 mm) and deep pockets, a wide range of tool holders was an important consideration,” explains Patrik Odermatt, the team leader of mechanical processing at Pilatus who is responsible for their internal division of tools. “Because our experience with their product quality, price-performance ratio, consultation and support has been very positive, we made the decision to continuously and solely rely on tool holding technology from them when it comes to our new manufacturing system.” The tool holders have provided long-term stability and run-out accuracy that has definitely paid off for his toolshop, which serves as the internal tool management service center for Pilatus and exclusively uses tools that are clamped into Haimer standard shrink fit chucks, ultra-short and long power shrink chucks, as well as power mini-shrink chucks, power collet chucks and special face mill arbors.

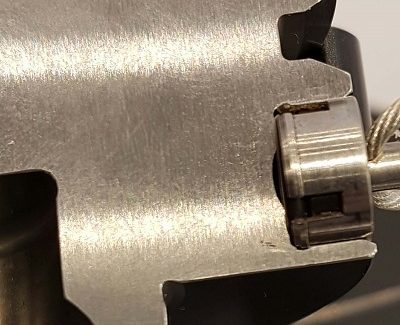

Odermatt also found flexibility regarding the spindle interface for the new manufacturing systems, which required a special HSK-A 63/80 tool holder. After close cooperation with the aircraft manufacturer, Haimer developed a program for this interface and added it to its standard delivery portfolio. And their patent-pending mechanical locking Data-Lock system that fixes the RIFD data carrier onto the tool holder has driven innovation at Pilatus, which uses this system to ensure that, even at the highest rpm, the data carriers are securely fixed and cannot separate from the tool holder. “The required parameters for every shrink fit chuck are already integrated into the shrinking machines,” noted Odermatt. “The performance and heating time are ideal and guarantee process-reliable shrinking at the push of a button. And balancing is also easy to perform.”

Pilatus Aircraft Ltd, Postfach 992, 6371 Stans, Switzerland, +41 41 619 61 11, Fax: +41 41 610 92 30, [email protected], www.pilatus-aircraft.com.

Haimer USA, 134 E Hill Street, Villa Park, IL 60181, 630-833-1500, Fax: 630-833-1507, www.haimer-usa.com.