The Hidden Champions: Punch-Laser Combination Machines

Once seen as a machine that can do anything but nothing to completion, there are now countless applications where the versatile punch-laser combination machine easily outperforms a laser cutting machine when a second application is included.

Posted: July 1, 2017

Modern sheet metal production has been trending toward flexible scheduling, small batch sizes and quick delivery times. For job shops, contract manufacturers and OEMs, keeping up with these increasing demands is more challenging than ever. To meet customers’ needs, new equipment with faster speeds, greater functionality and higher reliability is essential. As machine tools advance, the production focus shifts from processing times to interruptions and costly follow-up activities, all of which negatively impact overall productivity. These include wait time until parts and skeletons have been sorted from the pallet, shutdowns caused by collisions involving parts tilting over, refinishing work on microjoints, and secondary operations such as tapping and countersinking.

Due to all of these factors, it is essential to consider non-value added time when working to maximize productivity. Non-value added time refers to the amount of production cycle time that does not directly produce goods.

One common mistake many shops make when considering waste is to compare the time it takes to manufacture a part strictly based on cycle time. A fabricator might record the time required for laser or punch processing and the time for secondary operations, but forget to account for the non-value added time and labor costs that are associated with transferring a part from one machine to the next. The ultimate goal of lean manufacturing operations is to handle a part as infrequently as possible and, whenever handling must occur, to perform as much of the required processing as possible at that machine. Punch-laser combination machines are ideal for this approach because they are able to support complete part processing. By limiting handling as well as secondary operations, they have a much greater impact than just the sum of their parts. Fabricators are able to eliminate inefficiencies across the board, including areas which can be more difficult to quantify or others that they may not even be aware of.

https://youtu.be/N-Wamncm8go

Combination machines offer all the same automation options as a standalone laser machine, but also include part sorting capabilities. With the advent and wide-spread acceptance of solid-state lasers, fiber laser cutting machines have increased cutting speeds by as much as 25 percent when compared to machines outfitted with a CO2 laser. With increased laser processing speed comes greater production capabilities, however, a true solution for part separation does not yet exist on a laser cutting machine. Current systems offer automatic loading of raw material and unloading of the completed nest. While the laser cutting machine can run unattended with this setup, an operator will eventually need to intervene to remove the finished parts from the skeleton. Many shops forget to consider this time-consuming task when they think of the overall time required for production.

Like laser cutting machines, modern punching and combination machines have also seen an increase in processing speed. Not only are users able to produce parts faster, punching machines offer the added flexibility for fabricators to sort parts unattended. Modern punching machines equipped with the right automation systems are able to load raw sheets of material, sort parts down part chutes, pick up parts and place parts onto an unloading area. The skeleton is removed to a separate area for full part sorting and material removal without any manual intervention or added time. These sorted parts can also be made available parallel to production so that they can be accessed at any time, even while the machine is in motion. They are also designed for unattended operation since the process can be monitored from loading raw material to the unloading of complete parts.

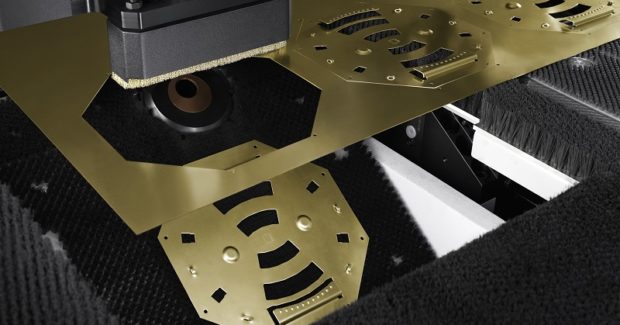

The fabrication shop also enjoys the benefits of having both technologies: the flexibility and high cut quality that is achievable with a laser machine and the efficient punching, unique forming operations and flexible part sorting capabilities of a punch machine. Parts that easily match the capabilities of this type of machine would therefore include forming requirements, such as tapping, countersinks or louvers, but would also have intricate contours or tangential junctures that require laser cut quality. On one side there’s the laser that can cut complex inner and outer contours with a perfect edge quality, and on the other side is the punching head that is extremely fast with punch patterns, e.g. with use of the cluster tool. This punch-laser combination machine can also form in any kind of shape and can do extrusions, countersinking, roller technology and much more.

This versatility makes a punch-laser combination machine the hidden champion in the industry. Once seen as a machine that can do anything but nothing to completion, there are now countless applications where this machine easily outperforms a laser cutting machine when a second application is included. Time studies show how they outperform a punching machine. They are the powerhouse that can work on a variety of jobs from start to finish. A single 2D laser machine has better specifications of laser cut speed, but when tapping or small bends are added to the part, the combo machines show their strength with complex outer inner and contour forming and sorting capabilities.

Although the technology is sometimes overlooked by fabricators who are considering the latest equipment offerings, a punch-laser combination machine offers all of the aforementioned advantages and is a worthy consideration for any shop. With it, fabricators are able to take advantage of all the latest advancements in laser technology to achieve the desired edge quality at very high cutting speeds, while also maintaining the freedom to form features, eliminate processing steps, simplify part sorting and facilitate unattended operation. If you are in the process of shopping for the next machine for your sheet metal production, consider a punch-laser combination machine.