The Chamfer that Changed the World

It all began with “Scuffgate,” a small chamfered edge that became a critical priority and evolved into a growing demand for fine finishes and feel in a world of myriad applications that only precision chamfering can deliver.

Posted: July 1, 2017

Chances are you’ve heard of DC’s “Watergate,” the NFL’s “Deflategate” or New Jersey’s “Bridgegate,” but what about “Scuffgate”? When Apple introduced the iPhone 5 it was a breakthrough in smartphone technology, but as the device started to make its way into the hands of users, some were finding scuffs on the phone exterior fresh out of the box, largely on the chamfered edges. The situation caused quite a stir, with the Internet and those in the press dubbing it “Scuffgate.” Built with lighter aluminum for the first time, technology experts posited that the natural softness of the metal was to blame, but it was hard to believe such widespread issues happened during packaging or shipping. This led others to point to potential deficiencies in the machining process.

It was maybe the most-talked-about chamfered edge ever. In fact, the issue made its way to the very top of the Apple chain of command . . . somewhat amazingly, a small chamfered edge had become a critical priority for one of the biggest companies in the world. Most machinists likely think of chamfering as just another finishing step to get through before moving a part out the door. However, this episode in consumer electronics history is the perfect illustration of the importance of consistently angled or rounded edges. As an operation that’s performed on nearly every workpiece, there is (of course) the safety concern of sharp edges, but there’s a growing demand for fine finishes and feel in a myriad of applications that only precision chamfering can deliver.

There’s no doubt that I see shops dedicating more thought and time to this process. But when it comes to the tooling being used, they’re often still trying to fit a square peg into a round hole, relying heavily on the accuracy of the machine instead of using a setup meant for the job. As we know, each component – from the cutting edge all the way back to the spindle housing – introduces variables and opportunity for error. While it may be light cutting, not using tooling that is tailored for the job can have consequences. For example, I often find chamfering performed with 90 deg-tipped drills or standard end mills with a tilted axis. That’s a demanding ask for a tooling assembly that isn’t designed to efficiently strike an edge in that way: it requires slower cutting speeds that extend cycle times and make fine finishes difficult, it strains tool life and increases consumable costs, and it requires more cutting and thrust force that translate into more energy consumption and machine wear.

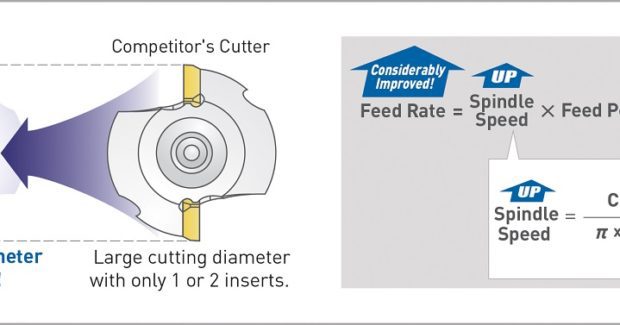

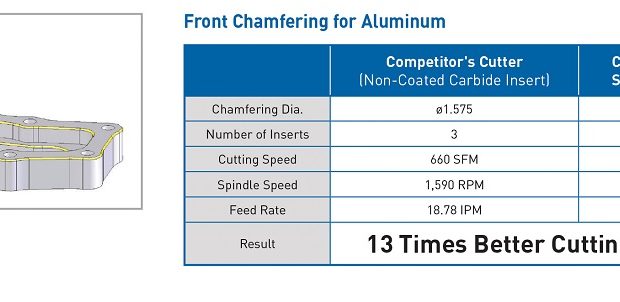

So just how can a simple tooling change make for better performing and more economical chamfering operations? Let’s start with feed rate, because higher feed rates not only reduce cycle time, but subsequently address some of the other issues as well. Increasing cutting speed capability and the number of teeth are two ways that a tool’s design can increase feed rate. For example, our C-Cutter Mini uses up to four inserts. The diameter of its tool body is built to the lowest limits to optimize chipload and spindle speeds in chamfering small and large features. This allows for very fast cycles. The inserts themselves also play a key role, so much so that they are among the only inserts we design in-house: extremely sharp edges with three types of coating reduce cutting resistance to help address speed, finish and force concerns that can arise, even on chamfers that require the tool’s maximum size capabilities.

In testing, this tool measured feed rates that were three times faster and a machining time that was less than 1/6 of a two-tooth alternative product. The versatility of chamfering tools can be impactful in key areas, too. Their capability to perform different types of processes, or even consolidate them, pays significant dividends. In this case, the C-Cutter Mini’s unique design and proprietary four-edged inserts allow users to back or front chamfer without dramatic setup changes.

In another scenario where the proper tool selection pays off, let’s say you have a part with 10,000 holes that all need to be chamfered. I see shops who think they are saving time by using a 90 deg chamfer to pilot. But when a deep hole drill with an angle of 140 deg has to enter a 90 deg hole, that’s not really piloting. The corners want to rip off. The sporadic life of high performance drills can often be attributed to this. A better tooling choice would be something like our double-degree Sphinx spot drill with a 142 deg angle that blends into a 90 deg angle up top. You’re giving that drill somewhere to enter without running it into a 90 deg angle. Not only does it combine and accelerate processes, but you’re stabilizing consumable expenditures along the way.

Speaking of consumables, if that’s your shop’s primary concern when it comes to chamfering operations, I’d be remiss if I didn’t mention how the indexable inserts on the C-Cutter Mini work. The four-sided design means you can turn the insert three times (assuming you’re performing only front or back chamfering) before they have to be scrapped. On the other hand, with a solid carbide chamfering tool, once it’s worn away it the whole tool has to be replaced.

The bottom line is this: Taking a little extra time to explore the chamfering tool options out there can save you a lot in the end, in terms of both time and money. It’s a process that may seem trivial, but there is a lot of opportunity to speed up cycles – even consolidate them – and save on consumable and energy costs, while delivering part quality that your customers are looking for more and more.