Multi-Process Welding in a Flexible, Rugged Package for Heavy Applications

Capable of gouging with up to a ½ in thick carbon steel, the Flextec 650X multi-process welder from Lincoln is ideal for large diameter stick, flux-cored, MIG or submerged arc welding on thick materials used in construction, shipbuilding and heavy fabrication.

Posted: July 17, 2017

The Flextec® 650X multi-process welder from The Lincoln Electric Company (Cleveland, OH) gives operators full functionality and control at the arc without an added control cable, thanks to its embedded CrossLinc® Technology. The Flextec 650X expands upon the well-established and proven Flextec 650 platform. It is rated at 650 amps, 44 volts at 100 percent duty cycle. It delivers up to 815 amps for heavy applications or a stable arc at low currents for MIG or TIG welding on thin materials. Typical applications include construction, shipbuilding and heavy fabrication. It’s ideal for large diameter stick, flux-cored, MIG or submerged arc welding on thick materials and is also capable of gouging with up to a ½ in (12.7 mm) carbon steel. The 650X yields a fast arc response, smooth arc action and smooth bead appearance on all DC wire, stick and TIG processes.

Using CrossLinc, the Flextec 650X now enables remote control of procedure settings at the arc. This leads to improved weld quality and increased productivity by reducing trips to the power source. It also improves safety by reducing jobsite cable clutter. With the Flextec 650X, CrossLinc can be used with an LN-25X feeder for wire fed welding processes or the new CrossLinc Remote for Stick, TIG or gouging processes. Broad wire-feeder compatibility is not an issue with the new Flextec 650X. It now is not only compatible with existing Lincoln Electric standard bench, boom and across-the-arc wire feeders, but it also is compatible with the CrossLinc-equipped and advanced digital ArcLink® feeders. With the addition of the ArcLink digital communications protocol, the Flextec 650X can be used with an expanded list of wire feeders compared to the previous 650 model. Applicable feeders include weld schedule memory storage to give operators easy recall of critical or often-repeated weld procedures. The Flextec 650X can be used with a wide range of available, three-phase input power. Engineered for outdoor use and harsh environments, the machine is IP23 rated. It also is Desert Duty® rated for extreme temperatures up to 55 deg C. Components are designed to run cool for long life in high-temperature environments.

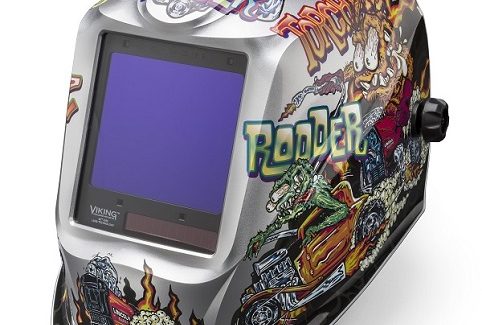

Lincoln Electric also offers their latest helmet design in the VIKING™ 3350 Series, the Hot Rodders™ concept that was inspired by classic hot rod cars. The hand-drawn artwork’s vibrant color scheme blends various welding and hot-rod-inspired themes to form a design intended for car enthusiasts from every era. There’s more to the VIKING 3350 helmet than its eye-catching graphics. It also provides premium optical clarity that is delivered in one of the industry’s largest viewing areas thanks to 4C™ Lens Technology. The 4C stands for the following attributes:

- Clarity – Optical clarity at the highest EN379 1/1/1/1 levels.

- Color – Real color view without a common green tint.

- Carat – Lightweight auto-darkening filter.

- Cut – Even shade from any angle.

This 4C technology reduces eye strain by minimizing the traditional green coloring in the helmet view screen in both active and inactive states. It is ideal for a range of industries that use multiple welding processes, such as SMAW, MIG and TIG, including general fabrication, power generation, shipbuilding, structural, offshore and pipeline. All of these helmets offer a pivot-style headgear designed for superior comfort and optimal fit. The helmets feature long battery life and a three-year warranty.

The Lincoln Electric Company, 22801 Saint Clair Avenue, Cleveland, OH 44117-1199, 888-355-3213, www.lincolnelectric.com.