Maintaining TCP: How Does Your Robotic MIG Gun Neck Factor In?

To maintain weld positions and weld in the same place every time, the MIG gun neck used in a robotic welding system must stay in its expected position as an accurate tool center point (TCP) that provides consistent repeatability from part to part. A weak neck that easily bends during routine welding can lead to problems with system accuracy over time. Here are some ways to protect, setup and maintain the neck and help ensure that your system maintains optimal TCP with minimal downtime.

Posted: July 1, 2017

A robotic MIG welding system contains many components that impact the quality of the parts it welds, its productivity and the overall operational costs. Among those, the robotic MIG gun neck plays a larger role than may first be apparent. Why? The durability of the gun neck – and especially its ability to withstand impacts – is important for maintaining tool center point (TCP). An accurate TCP provides consistency and repeatability from part to part and is key to the system’s ability to maintain weld positions, especially in assembly line welding where new parts are continually entering the weld cell. A productive and efficient robotic welding system places welds in the same place every time. To achieve this consistent repeatability, the MIG gun neck needs to stay in its expected position. A weak neck that easily bends during routine welding can lead to TCP problems over time, as can rough handling of the neck during consumable changeover.

Issues with TCP can lead to additional spatter or missed welds that cause rework or scrapped parts. These cost time and money in lost productivity and in wasted parts. An inaccurate TCP can also cause the neck to crash into parts or tooling, potentially leading to equipment damage and unplanned downtime. When selecting a robotic MIG gun neck, look for durable, high quality materials and robust construction. The goal is to have a neck that is strong enough to withstand minor crashes without bending. In addition, be certain there is a solid connection from the neck to the gun, and from the gun to the mounting arm in a conventional system or to the robot itself in a through-arm system. Any play in the system can negatively impact TCP.

AIR-COOLED OR WATER-COOLED GUN?

Neck durability varies depending on whether the application uses an air-cooled or a water-cooled robotic MIG gun. Some applications require water-cooled guns to protect the gun and the neck in high temperature continuous welding. However, these guns tend to be less durable in a crash than air-cooled gun necks due to the internal soldering of copper and brass lines for the water passages. Air-cooled guns, by comparison, typically feature copper tubes covered with insulation and aluminum that makes them stronger and more able to resist an impact. Some manufacturers offer a hybrid air/water-cooled robotic MIG gun in which the water lines run external to the neck. This type of gun tends to have a stronger neck, similar to an air-cooled gun, which makes it more tolerant to crashes. However, it is important to ensure that the water lines do not hit tooling or parts, which can negatively affect TCP or create leaks.

https://youtu.be/f0DgVx2oGCM

GETTING THE BEST PERFORMANCE

Some key best practices can help protect the neck and provide consistent TCP:

- All robotic welding systems require a form of collision detection to prevent damage to both the robotic MIG gun and the robot arm in the event of an impact. Some robotic systems incorporate robot collision detection software. Systems that do not have built-in collision detection should always be paired with a clutch: an electronic component that attaches to the gun to protect it and the robot from heavy damage in the event of a collision.

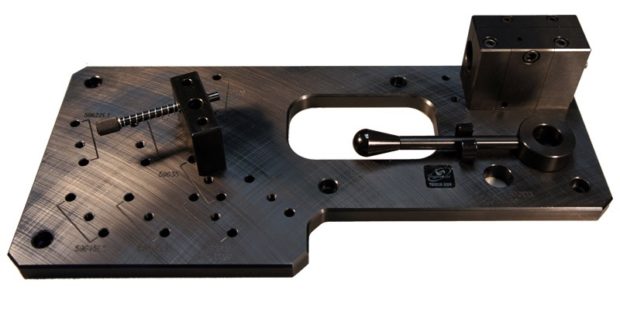

- Another key peripheral is a neck inspection fixture that verifies the gun’s neck is set to the intended TCP and allows the neck to be readjusted after a collision or if it becomes bent during routine welding. If neck adjustment is needed, the welding operator simply adjusts the neck to meet the proper specifications. This prevents costly rework due to missed weld joints and can reduce downtime involved in having to reprogram the robot to meet the welding specifications with a bent neck.

- Having spare necks ready helps gets the system back online quickly. The welding operator need only remove the bent neck in the event of a crash and exchange it with a spare one. The damaged neck can be set aside for inspection later, minimizing interruption to the weld cycle.

- Choose a high quality reamer to avoid potential damage to the gun or neck. A reamer, or nozzle cleaning station, removes spatter from the nozzle and clears away the debris that accumulates in the diffuser during welding. A high quality reamer securely holds the gun in place during the ream cycle to reduce the risk of bending the neck and compromising TCP.

- Proper neck and consumable installation and ongoing maintenance are important. Make sure to tighten these components to factory specifications. When changing consumables, remove them with the right tools to avoid bending the gun neck.

In many cases, a robotic welding system can provide a competitive edge that offers greater productivity, quality and cost savings. Take care to protect the MIG gun neck and follow best practices for setup and maintenance to help ensure the system maintains optimal TCP and the operation experiences minimal downtime.