Innovative Robotic Roll Forming System

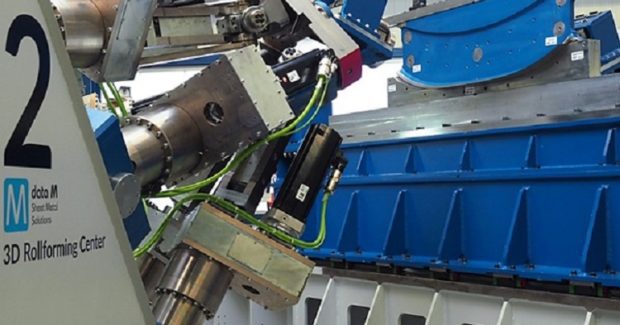

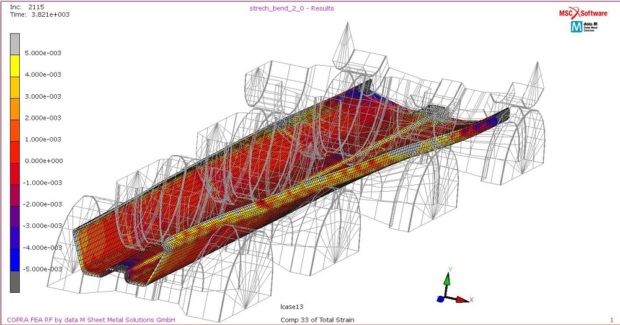

The 3D Rollforming Center from data M Sheet Metal Solutions uses an integrated hexapod robot to produce high strength steel or aluminum alloy profile sections that vary in height and width, a COPRA ProfileScan Desktop measurement device for quality control of profiles, and COPRA FEA RF design and simulation software to validate the roll forming process.

Posted: July 21, 2017

In Booth 2134, data M Sheet Metal Solutions (Valley, Germany) will display their innovation 3D Rollforming Center®, the first robotic roll forming machine that can produce high strength steel or aluminum alloy profile sections that vary in height and width for automobile and aerospace component suppliers, steel or aluminum producers, or research institutes. This Industry 4.0 system validates the forming process with COPRA® RF and COPRA FEA RF design and simulation software for roll forming and uses an integrated hexapod robot for low volume production or rapid prototyping through advanced control units and sensor technology connected to COPRA ProfileScan Desktop and COPRA RollScanner measuring systems for efficient quality control of products and roll tools.

Data M Sheet Metal Solutions GmbH, Am Marschallfeld 17 83626 Valley, Germany, +49 (0) 8024-640-0 Fax: +49 (0) 8024-640-300, [email protected], www.datam.de.