Consider the Source

Some machinists go into business for themselves as a part-time hobby, while others dream of becoming an OEM supplier. Here are two shops that online manufacturing marketplace MFG.com helped to source the work they needed to get off the ground and fulfill their dreams.

Posted: July 12, 2017

HOW TO ENTER THE OEM SPACE

Founded in 1984, Riverside Industries LLC (Huron, SD) is a full line steel, stainless steel and aluminum distributor of sheet, plat and tubing products and an ISO-compliant shop that offers laser cutting, forming and fabrication services, as well as AutoCAD and SolidWorks drafting. They employ approximately ten people, occupy a 38,000 sq ft manufacturing facility, and pride themselves on a reputation for uncompromising quality, outstanding service, customer loyalty and fair pricing.

“We purchased the company in 2015 with the idea of eventually entering the OEM (original equipment manufacturer) space,” recalls Jerome Waldner, their shop foreman. “However, we first needed to identify work and find custom jobs to support the shop until our own product line got off the ground.” In the summer of 2016, Jerome and his brother John, the chief executive officer of the company, looked to MFG.com (Atlanta, GA), a leading global marketplace that brings buyers and suppliers together, to be the source of the work they sought to sustain their shop. Upon activating their subscription, they took advantage of the wide-ranging training that this online marketplace provides. After learning the mechanics of the website and the variety of tools at their disposal, they set up searches that focused on work involving stainless and carbon steel, because machining with sheet metal is the shop’s specialty.

Nine months later Jerome reported that work identified via the online marketplace constituted 50 percent of his shop’s production. He’d offered quotes on 265 RFQs and been awarded 61 jobs to date, with work orders ranging from one part to 750 pieces and 50 percent of those involving aluminum and carbon steel. He indicated that he has connected with some bigger companies via the online site and established some excellent business relationships. Much of this work involves laser cutting, which is another specialty of his firm. “The buyers I work with come from all over the United States and represent a variety of industries,” notes Jerome. “We go with the flow and take whatever work comes our way.”

Riverside has benefited a lot from using ShopIQ, a site tool offered to subscribers to help them benchmark their quotes against their competitors. “It educated us on how to be competitive with other U.S. manufacturers,” explains Jerome. “Our bids were too high at first, but now I’ve got a firm grasp on my bidding strategy. We are regulated now. The practice has been good for us.” He also indicated that buyer ratings have assisted his success on the site. So far, the company has received six or seven ratings, which he feels were both fair and accurate. When asked if these facilitated job wins, Jerome says, “They help us a lot. We even got a five-star rating. All the work we’ve been doing has helped us become more efficient with our tooling, too. Being more efficient saves time and money for us and our buyers.”

“MFG.com allowed us to fulfill our dream of being able to make OEM products on the side,” adds Jerome. “Beyond giving us much-needed work experience, those jobs provided us with the monetary resources to start making prototypes. We are now ready to market the products that we’ve built in-house, such as our own lift table.” Interestingly, their in-house product line includes imaginative ways to recycle old thrash wheels into a pneumatic row cleaner for agriculture, an apple press, a dumpster and part box, a shop press and a vegetable press.

“Our idea of entering the OEM space is now almost a reality thanks to this online marketplace,” concludes Jerome. “The work we won in the marketplace supported our operations as we designed our product line and perfected our prototypes. And that work provided us the opportunity to hone our shop skills and be more efficient across the board. Now, MFG.com awards will help support us as we market our product line, along with the ongoing business contacts we’ve made on that platform. We are most grateful to them for the role they’ve played in our business development.”

Riverside Industries LLC, 40361 200th Street, Huron, SD 57350, 605-350-9022, [email protected], riversideindustriesllc.com.

COMPETING OUTSIDE THE BOX

Troy Donath started TD&M Machining LLC (Dubuque, IA) in 2007 as a part-time venture with the long-term goal of becoming his own boss. He began the company in his garage and relied on a single two-axis manual machine tool. At first, the pace of the work suited his availability but, at the end of 2008, Donath was laid off from his full-time job and needed to grow his business to support his family. “Within a 50 mile radius of Dubuque, there are many machine shops,” he says. “The competition for work is fierce and everyone knows everyone else here. Shop owners do not take kindly to other shops trying to solicit their customers. I didn’t want to get involved in this sort of competitive environment, so I decided to seek work from outside the area.”

With a limited budget, Donath could not afford to hire a sales staff so he looked to the Internet as a resource and searched on the term “outsourced machine parts” and found MFG.com. He checked out the online marketplace, decided to do a three-month trial subscription, and took advantage of the training that the site provides initially. “I don’t learn well by listening to other people talk or watching demonstrations,” he said. “I am a hands-on person, so I figured out the website mechanics on my own. At first, the subscription was pretty pricey for me, but I stuck with it and landed some decent customers. They didn’t care that I was working out of my garage as long as the parts were good. And because this marketplace is all over the world, I found customers on both coasts. None are from the Dubuque area, so I don’t have to worry about competitors saying I took their customers.”

Donath shares that he likes the online marketplace because he can use it as he needs it: “If I get busy and don’t need new work, I won’t look at it for a while. I don’t have to constantly quote all the time. But if I see a drop in work, I get back on and pick up another customer.” TD&M Machining has experienced nothing but growth since landing those first two customers on MFG.com. While still operating out of his garage, Donath hired a neighbor on a part-time basis to help run parts. Later he took on a business partner and moved into a 1,000 sq ft facility. The shop then acquired one horizontal mill and two vertical mills and hired two full-time workers.

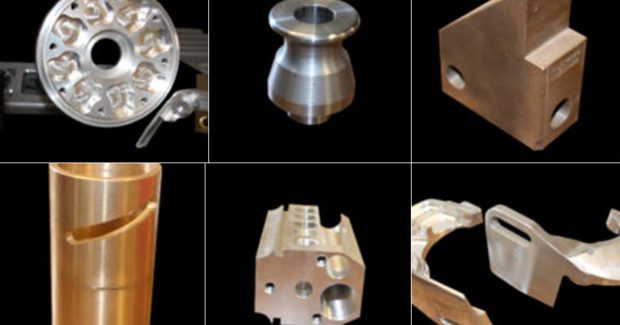

Later, in 2014, Donath bought out his business partner. Now the company specializes in CNC 2D machining, 3D machining, modeling, turning, surface grinding and heat treating that are focused on all types of steel, aluminum and plastics. The latest sales are about $700,000 and the firm has six CNC machine tools (a horizontal mill, four vertical mills and a CNC lathe) and employs 5.5 full-time equivalents.

“We do job shop work that is mostly one-offs and one to five parts,” notes Donath. “We basically do whatever comes in the door. I probably have gotten over 100 jobs from the online marketplace. Many are now repeat customers that give me work all the time. Once I do a job and they like it, we deal offline. I’d say about 75 percent of our current customers came from MFG.com, and four to five of those are our top sources of revenue. We do a lot of parts for one company that manufactures and sells splicing, stripping and cleaning machines for the fiber optics sector. We do small aluminum pieces, perhaps one part to five parts with 20 pieces to 25 pieces per order. Another customer is in road construction and builds scrapers that they retrofit with articulating trackers. We machine a lot of parts for them in Hardox 450.”

Donath says that, for the most part, the buyers he’s dealt with in the online marketplace are great: they want a decent product at a decent price and they pay on time. Some jobs even hold surprises. “About a year ago I saw that the Massachusetts Institute of Technology (MIT) had some parts up for bid,” recalls Donath. “I was a bit skeptical, but submitted a quote nonetheless. Later, a student calls me to talk about getting the parts machined. He says, ‘I like your work, but time is a constraint.’ I said we could work on his schedule. It turns out the parts were for a robot that MIT was building for the television show ‘BattleBots,’ where competitors design and operate remote-controlled robots that fight in an elimination tournament. The parts we made were part of a battle bot in the television series. MIT sent me pictures showing me the location of the parts I machined. It was pretty exciting.”

Donath feels that MFG.com played an important role in growing his business: “Using them is like having a salesperson on staff working for you 24/7. Every day they identify work for my consideration and allow me to bid on those jobs that match our skillsets. If I don’t need work or new customers, then I don’t have to use them. MFG.com is a great resource that’s constantly at the ready for shops of every size.”

After ten years of using the online marketplace, Donath sees no end in sight. “I have three to four customers I found through them that account for most of my revenue,” he says. “I’d like to find one or two more clients like them. That is one reason why I keep subscribing. Another is unpredictability. One of my first and best MFG.com customers decided to take their work back in-house when new management took over. You never know what life holds, but I know I can always count on this online marketplace for the work my shop needs.”

TDM Machining, LLC, 3176 Cedar Crest Ridge,Dubuque, IA 52003, 563-513-4230, Fax: 563-845-0023, [email protected], tdmmachining.co.