Rapid Metal Analysis Reduces Shop Downtime

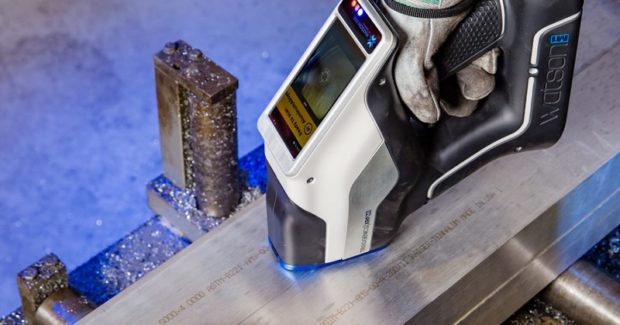

Ideal for metal fabrication and machining of parts used in the aerospace, automotive, medical, military, scientific and general industrial sectors, the Watson XRF Handheld Metal Analyzer from Tribogenics performs reliable positive materials identification of metal alloys in seconds, with onboard calibration and cloud reporting of results.

Posted: June 1, 2017

As more metal fabrication shops become increasingly concerned about the quality of the metals coming into their plants from overseas, the need for a reliable verification technology to quickly and accurately check the conformance certificates that typically accompany these metal alloys is increasing. Tribogenics (Los Angeles, CA), the inventor of breakthrough Tribo-electric™ based X-ray technology for industrial materials identification applications, offers their award winning Watson™ XRF Handheld Metal Analyzer. Powered by Tribo-electric technology, Watson features the world’s first ever M1 X-Change™ X-ray source to guarantee constant uptime – a first for users of handheld XRF devices. It is commonly used in metal fabrication and machining of parts used in the aerospace, automotive, medical, military, scientific and general industrial sectors.

For example, GE Aerospace now requires their suppliers to use a verification technology to double-check the quality of their metals. The handheld Watson XRF analyzer provides a low-cost insurance policy for these shops by performing reliable positive materials identification (PMI) of metal alloys in seconds. The new technology that drives Watson makes this device the lowest cost metal analyzer in the market, with features that include a field exchangeable X-ray cartridge that works just like an inkjet printer, making downtime a thing of the past, onboard calibration and cloud reporting of results. This handheld analyzer delivers significant benefits for metal fabricators in terms of affordability, ease of use, portability, rapid metal analysis and reduced downtime in the field. It removes the risk of error in manufacturing QA/QC environments by performing non-destructive testing (NDT) and PMI of metals and alloys.non-destructive testing

Tribogenics, 5440 McConnell Avenue, Los Angeles, CA 90066, 855-972-9123, tribogenics.com.