New Paths for Mobile Robotics

As shops face the pressures of mass customization, changing requirements and labor shortages, innovative autonomous industrial mobile manipulators are being introduced to relocate the robot arm throughout the facility to perform different tasks, such as part replenishment, machine loading or fulfillment, and more.

Posted: June 24, 2017

Every day, manufacturers look for ways to improve efficiency and productivity. Frequently this has meant automating functions with robots that can ensure consistent quality and perform dangerous or repetitive tasks, reducing employee health issues and freeing up valuable human resources to contribute to other production areas. Many of these mundane tasks have already been automated with traditional robotics. As shops continue to face the pressures of mass customization, changing requirements and labor shortages, new ways to utilize robotics are being introduced. One of these is mobile robots, which can include:

- Devices that can manually be moved as needed.

- Autonomous mobile robots (AMR) that can deliver parts and materials throughout the factory.

- Fully functional robot manipulators that move through the plant, essentially taking the robot to the work versus bringing the work to the robot. These latest innovations are sometimes referred to as autonomous industrial mobile manipulators (AIMM). These are the devices we will now explore.

First, what is an autonomous mobile robot? An AMR is a robotic platform designed to function independently of its surroundings. The unit is completely autonomous, which means it can navigate anywhere within the factory or distribution center, while being managed by a central software system. The nature of these devices allows them to be implemented without the need for new infrastructure to guide the units, such as tracks, tape or guide posts. The factory or distribution center is “mapped out” by the autonomous robot so that it knows how to get from location to location. Many autonomous robot vendors have emerged, most of whom target the movement and delivery of smaller payloads (less than 100 kg). These devices can ferry cargo or parts throughout the facility or even deliver racks of various components to work stations. Other vendors have even implemented platforms with payloads upwards of 1,500 kg, enabling movement of compete subassemblies.

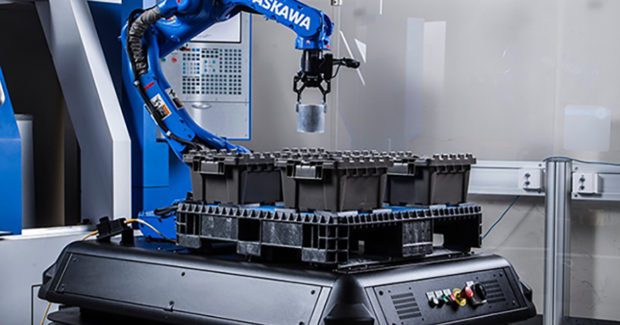

A new generation of these autonomous devices is now being coupled with a robotic arm or manipulator. These AIMMs can relocate the robot arm throughout the facility to perform different tasks, such as part replenishment, machine loading or fulfillment, but is this the logical next step? Let’s look at a few scenarios.

MULTIPLE MACHINE TENDING

Do you have a shop environment where parts need to be moved between multiple industrial machines during the manufacturing process? Maybe the work orders are flexible to the point where the use of the machines changes daily. What if the machines are not fully utilized due to lack of staffing? What if you could have a robot automatically move between workstations, carrying parts as needed to the next manufacturing process?

Watch out. Here comes a mobile vehicle with a 10 kg payload robot arm and all the safety features required to address any risk assessment concerns (an AIMM). Perhaps the robot is even one of the new collaborative robots designed to work easily in small confined spaces alongside human workers. Based upon system production requirements and direction from your enterprise resource planning system (ERP), the vehicle, robot arm and parts are automatically dispatched to the proper workcell. Maybe the AIMM loads the machine and moves on to another workstation while the first part is processed. After delivering several components, the AIMM returns to collect and distribute the part(s) to other workcells or to the next production process – all without human intervention.

Is autonomous machine tending useful? Can you envision a system as described, automatically responding to system requests to load, unload and process parts? What requirements would have to be satisfied to make this a reality?

PARTS DELIVERY/REPLENISHMENT

A key use case for autonomous industrial mobile manipulators is parts delivery or bin replacement. As production progresses, workstations need to be replenished with parts. Autonomous vehicles can automatically retrieve bins with new parts or even transport complete racks of parts to the appropriate workstation. They can then return the empty bin or cart and repeat the process. Part of the issue is that you may still need a human worker at each end to load the new parts or unload at the destination. What if the AIMM could load the parts at the pickup spot and unload them at the delivery point? This would also enable deliveries to be customized based upon production requirements, but safety continues to be an issue. As the robot is unloading the parts, safety scanners and/or collaborative technology is required to protect workers.

Is there a need for automatic and autonomous delivery of parts? Are there other challenges besides safety that must be addressed? Think about it.