Double Metal Sheet Detection for Metal Stamping

Ideal for automation applications in robotics, automated de-stackers, sheet feeders and in-fixture (poke-a-yoke) where sensing from only one side is possible, the DS600 Double Sheet Detection Control from Prime Controls detects metal thickness and prevents double sheets or improper thicknesses from entering machines.

Posted: June 1, 2017

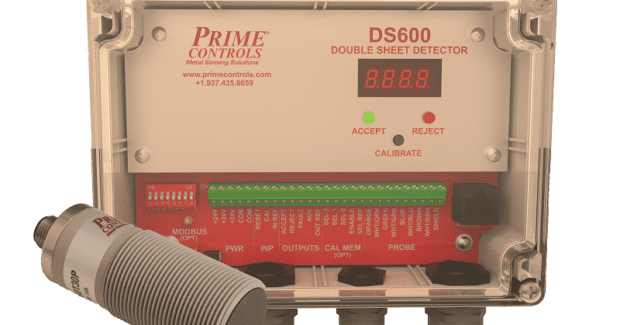

Prime Controls, Inc. (Dayton, OH), a leading manufacturer of double metal sheet sensors and controls for the can making, automotive, appliance and other metal forming industries, offers their new DS600 Double Sheet Detection Control. Paired with a non-contact, single probe sensor, the DS600 control detects non-ferrous metals (such as 300 series stainless steel and aluminum) with thicknesses ranging from .025 mm to 3.81 mm (.001 in to .150 in). By measuring the effects of eddy currents on the non-ferrous metal near its face, the DS600 is able to detect the metal thickness and prevent double sheets or improper thicknesses from entering machines, ultimately diminishing costly repairs and downtime. This is especially important for automotive metal stampers, where the industry is utilizing more and more non-ferrous metals to reduce the weight of vehicles.

Unlike other single probe double sheet detectors on the market, the DS600 system does not need to make contact with the metal it measures, helping to avoid surface defects to the product. Housed in an IP65-rated enclosure, the DS600 unit is thoroughly protected in the typical shop floor environment. This system is well suited for automation applications such as robotics, automated de-stackers, sheet feeders and in-fixture (poke-a-yoke) where sensing from only one side is possible.

Three versions of the control are available to better suit application needs: The basic DS600 model is geared towards applications where the need for simply detecting whether a single or double is present is the main objective. For applications that require additional features and functionality, the DS600 Premium is available. A hands-off product, the DS600 Premium offers eight-slot calibration memory, easily selected through discrete I/O, for quick change-overs with no recalibration required. It also provides threshold adjustments and variable timing during the detection process for better gauging of metal thickness and more defined. With the growing demand for communication capability among the system controls and customer’s PLCs, the DS600 PremiumPLUS features industrial communications in addition to 64-slot calibration memory and memory backup to ensure the users receives the most out of their system.

Prime Controls, Inc., 4528 Gateway Circle, Dayton, OH 45440, 937-435-8659, Fax: 937-435-2109, [email protected], www.primecontrols.com.